Yiziphi izinkinga ezivamile nezisombululo zamavalvu ovemvane ngesikhathi sokusetshenziswa?

I-valve ye-Butterfly ngenxa yobukhulu bayo obuncane kanye nesakhiwo esilula, isiphenduke enye yama-valve asetshenziswa kakhulu embonini, asetshenziswa kakhulu amandla kagesi ngamanzi, ukuchelela, ukwakhiwa kwamanzi kanye nokukhipha amanzi, ubunjiniyela bakamasipala nezinye izinhlelo zamapayipi, ezisetshenziselwa ukunqamula noma ukulamula ukugeleza kokugeleza kwemidiya ezungezayo ozokusebenzisa.Khona-ke i-valve ye-butterfly ekusetshenzisweni kwezinkinga ezidinga ukunakwa nezixazululo kulokho, namuhla sizobe siqondile ukuqonda.

Ukufakwa kwe-Butterfly valve kudinga ukunakwa:

1.Ngaphambi kokufaka, sicela uqinisekise ukusebenza komkhiqizo kanye nomcibisholo wokugeleza kwemidiya uhambisana nokuhamba kwezimo zokusebenza, futhi kuzoba imbobo ye-valve ekhuhlwe, ingavumeli ukungcola kwendandatho yokuvala kanye nepuleti levemvane elinamathiselwe ezintweni zangaphandle, hhayi ukuhlanzwa ngaphambi kwanoma yikuphi ukuvunyelwa ukuvala ipuleti yevemvane, ukuze ungalimazi indandatho yokuvala.

2.Disc ukufakwa ipuleti asekelayo flange Kunconywa ukusebenzisa flange uvemvane valve ekhethekile.

3.Kufakwe phakathi kwepayipi noma indawo yeziphetho ezimbili zepayipi, indawo engcono kakhulu yokufakwa okuqondile, ayikwazi ukufakwa ibheke phansi.

4. Ukusetshenziswa kwesidingo sokulawula ukugeleza, kukhona ama-manual, kagesi, ama-actuator we-pneumatic wokulawula.

5. Vula futhi uvale ngokuvamile uvemvane valve, cishe izinyanga ezimbili, kudingeka uvule isembozo gear ibhokisi worm, hlola ukuthi ibhotela kuyinto evamile, kufanele ugcine inani elifanele ibhotela.

6.Hlola ukuthi izingxenye zokuhlanganisa zicindezelwe yini, okungukuthi, ukuqinisekisa ukuvala ukupakisha, kodwa futhi ukuqinisekisa ukuthi ukujikeleza kwe-valve stem kuyaguquguquka.

7.Imikhiqizo ye-valve butterfly seal yensimbi ayifanele ukufakwa ekupheleni kwepayipi, njengokuthi kufanele ifakwe ekupheleni kwepayipi, udinga ukuthatha i-flange yokukhipha efakiwe, ukuvimbela ukunqwabelana kwendandatho yokuvala ingcindezi, ngaphezulu. isikhundla.

I-8.Ukufakwa kwe-valve stem kanye nokusetshenziswa kwempendulo ukuhlola njalo ukusebenza kwe-valve, kutholwe amaphutha ngesikhathi esifanele.

Izimbangela ezingenzeka zokwehluleka: ukuvala ukuvuza kwendawo

Ipuleti le-1.Valve, imfucumfucu yefolda evala uphawu

Ipuleti le-2.Valve, indawo yokuvala indawo yokuvala ihambisana nokungalungile

3.I-Outlet side yokucushwa ifaka amabhawodi e-flange amandla angalingani noma amabhawodi axegayo

4.Isiqondiso sokuhlolwa kokucindezela asihambisani nezidingo zesiqondiso sokugeleza okuphakathi.

Izindlela zokuqeda

1.Susa ukungcola, hlanza i-valve yangaphakathi

2.Lungisa igiya lesikelemu noma izikulufu zikagesi, i-pneumatic actuator ukuze ufinyelele indawo efanele yokuvalwa kwevalvu.

3.Ukuhlola indiza ye-flange efakiwe kanye ne-bolt compression fastening, kufanele kucindezelwe ngokufanayo

4.Ngokwendlela yokuvala umcibisholo ukuze uthole ingcindezi

Izimbangela zokuvuza kwe-valve ezimbili ziphela

1.Zombili izinhlangothi zokuhluleka kwe-gasket yokuvala

I-2.Ukuqina kwe-Pipe flange akufani noma akucindezelwe

3.Indandatho yokuvala noma indandatho yokuvala ekuhlulekeni kwe-gasket

Indlela yokuqeda

1. Faka esikhundleni i-gasket yokuvala

2.Amabhawodi e-pressure flange (amandla afanayo)

3.khipha indandatho ye-valve yokucindezela, buyisela indandatho yokuvala kanye nokuhluleka kwe-gasket.

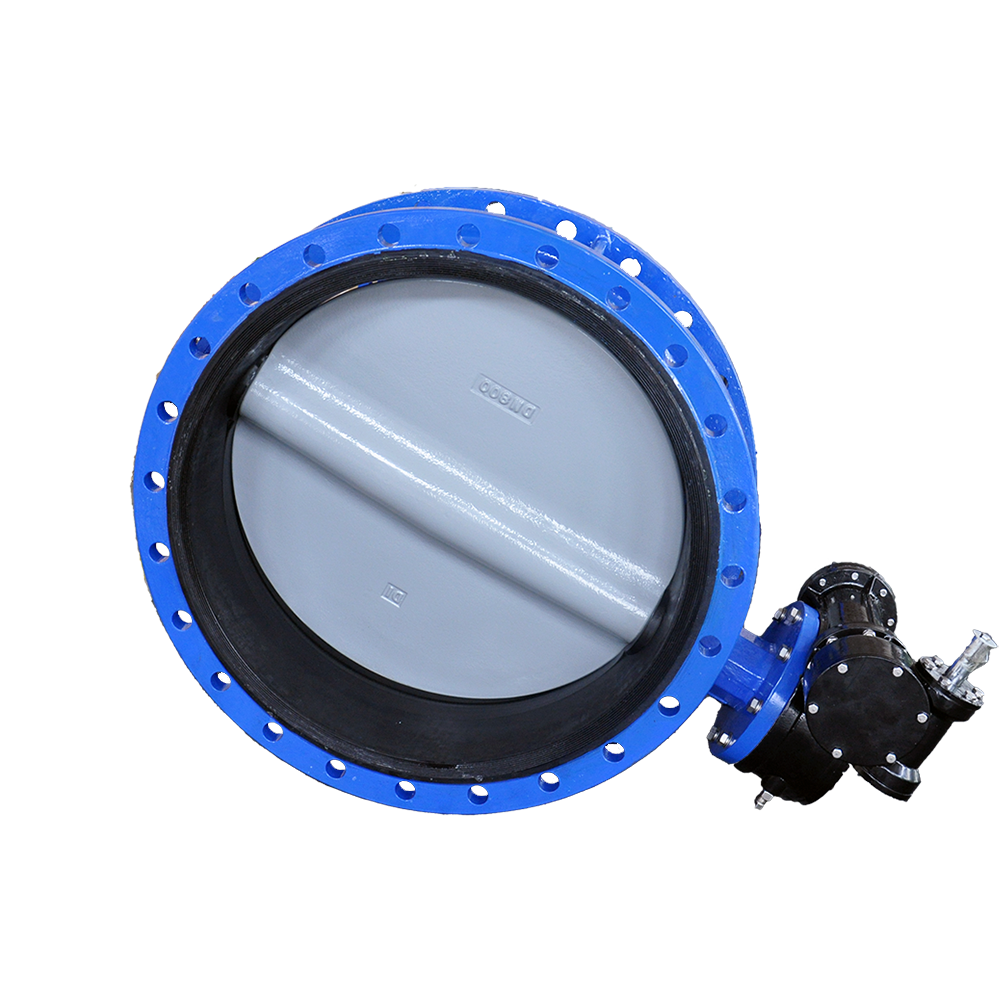

I-valve yovemvane ingahlukaniswa ngomugqa ophakathi uvemvane iveve kanye ne-eccentric butterfly valve ngokuya ngesakhiwo.Ngokusho ifomu lokubeka uphawu zingahlukaniswa zibe soft uhlobo uphawu futhi uhlobo uphawu oluqinile.Uhlobo oluthambile lokuvala ngokuvamile lusebenzisa isihlalo se-valve yenjoloba noma ukuvala indandatho yerabha, uhlobo oluqinile lokuvala ngokuvamile lusebenzisa ukuvala indandatho yensimbi.Ngokusho kohlobo lokuxhuma, ingahlukaniswa ibe uxhumano lwe-flange nokuxhumeka kwe-wafer;ngokwemodi yokudlulisa, ingahlukaniswa ibe imanuwali, kagesi, i-pneumatic kanye ne-hydraulic.Singakhetha ama-actuator ahlukene ngokuya ngezimo zokusebenza.