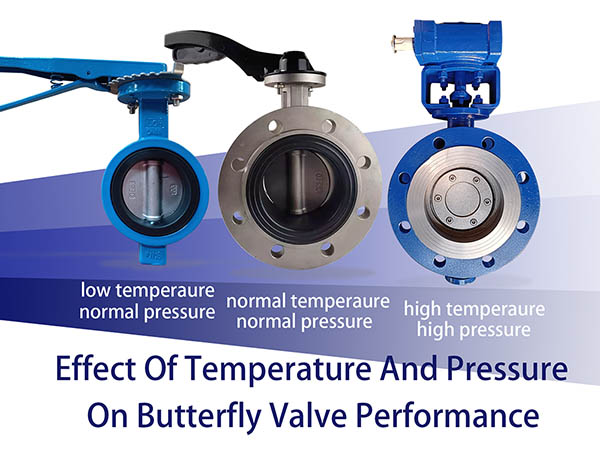

Umthelela Wezinga Lokushisa Nokucindezela Ku-Butterfly Valve Performance

Amakhasimende amaningi asithumelela imibuzo, futhi sizophendula sibacela ukuthi banikeze uhlobo oluphakathi, izinga lokushisa eliphakathi nokucindezela, ngoba lokhu akuthinti kuphela intengo ye-butterfly valve, kodwa futhi kuyisici esiyinhloko esithinta ukusebenza kwe-valve butterfly.Umthelela wabo ku-valve uvemvane uyinkimbinkimbi futhi ubanzi.

1. Umthelela Wezinga Lokushisa Ekusebenzeni Kwevaluvu Yevemvane:

1.1.Izinto ezibonakalayo

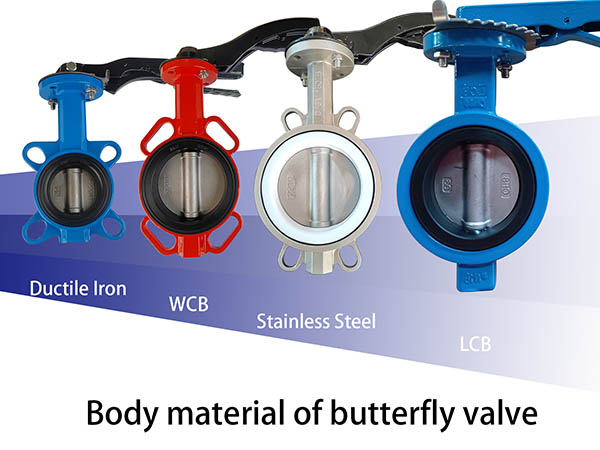

Ezindaweni ezinokushisa okuphezulu, izinto ezifana nomzimba we-butterfly valve kanye ne-valve stem zidinga ukumelana nokushisa okuhle, ngaphandle kwalokho amandla nobulukhuni kuzothinteka.Endaweni yokushisa ephansi, i-valve yomzimba izoba brittle.Ngakho-ke, izinto ze-alloy ezikwazi ukumelana nokushisa kumele zikhethelwe izindawo ezinokushisa okuphezulu, futhi izinto ezinokuqina okuhle kokumelana nokubanda kufanele zikhethelwe izindawo ezisezingeni eliphansi lokushisa.

Sithini izinga lokushisa lomzimba wevalvu uvemvane?

I-Ductile iron butterfly valve: -10 ℃ kuya ku-200 ℃

I-WCB butterfly valve: -29℃ ukuya ku-425℃.

SS uvemvane valveUkushisa: -196 ℃ kuya ku-800 ℃.

I-valve uvemvane LCBUkushisa: -46 ℃ kuya ku-340 ℃.

1.2.Ukuvala Ukusebenza

Izinga lokushisa eliphakeme lizokwenza ukuthi isihlalo se-valve ethambile, indandatho yokuvala, njll. ithambe, yande futhi ikhubazeke, inciphise umphumela wokuvala;kuyilapho izinga lokushisa eliphansi lingase lukhuni impahla yokuvala, okuholela ekwehleni kokusebenza kokuvala.Ngakho-ke, ukuze kuqinisekiswe ukusebenza kokuvala ezindaweni zokushisa eziphakeme noma eziphansi, kuyadingeka ukukhetha izinto zokuvala ezifanele izindawo zokushisa eziphezulu.

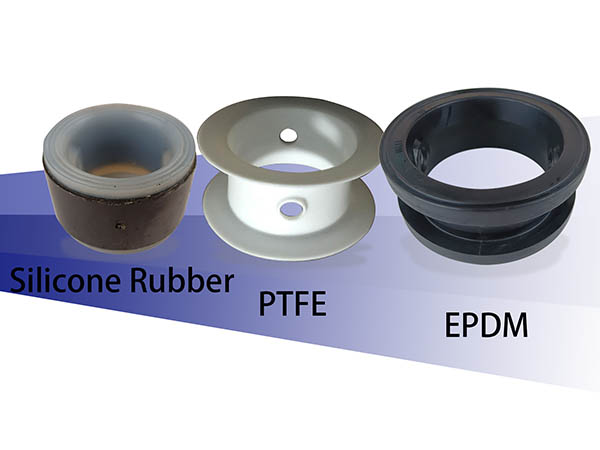

Okulandelayo yizinga lokushisa lokusebenza kwesihlalo se-valve ethambile.

• I-EPDM -46℃ – 135℃ I-Anti-aging

• I-NBR -23℃-93℃ Imelana Nowoyela

• I-PTFE -20℃-180℃ I-anti-corrosion nemidiya yamakhemikhali

• I-VITON -23℃ - 200℃ I-Anti-corrosion, ukumelana nokushisa okuphezulu

• I-Silica -55℃ -180℃ Ukumelana nokushisa okuphezulu

• I-NR -20℃ - 85℃ Ukunwebeka okuphezulu

• CR -29℃ – 99℃ I-Wear-resistant, anti-aging

1.3.Amandla esakhiwo

Ngikholwa ukuthi wonke umuntu uzwile ngomqondo obizwa ngokuthi "ukunwetshwa okushisayo nokufinyela".Ukushintsha kwezinga lokushisa kuzodala ukuwohloka kokucindezeleka okushisayo noma imifantu emalunga namavalvu evemvane, amabhawudi nezinye izingxenye.Ngakho-ke, lapho uklama futhi ufaka ama-valve e-butterfly, kuyadingeka ukucabangela umthelela wokushintsha kwezinga lokushisa esakhiweni se-butterfly valve, futhi uthathe izinyathelo ezihambisanayo zokunciphisa umthelela wokwandisa nokunciphisa okushisayo.

1.4.Izinguquko ezicini zokugeleza

Ukushintsha kwezinga lokushisa kungase kuthinte ukuminyana kanye ne-viscosity ye-fluid medium, ngaleyo ndlela kuthinte izici zokugeleza kwe-valve uvemvane.Ekusetshenzisweni okungokoqobo, umthelela wokushintsha kwezinga lokushisa ezicini zokugeleza udinga ukucatshangelwa ukuze kuqinisekiswe ukuthi i-valve uvemvane ingahlangabezana nezidingo zokulawula ukugeleza ngaphansi kwezimo ezihlukahlukene zokushisa.

2. Umthelela Wengcindezi Ekusebenzeni Kwevalve Yevemvane

2.1.Ukusebenza kokuvala

Lapho umfutho we-fluid medium ukhuphuka, i-valve uvemvane idinga ukumelana nomehluko omkhulu wengcindezi.Ezindaweni ezinomfutho ophezulu, ama-valve ovemvane kudingeka abe nokusebenza okwanele kokuvala ukuze kuqinisekiswe ukuthi ukuvuza akwenzeki lapho i-valve ivaliwe.Ngakho-ke, indawo yokuvala yama-valve emvemvane ngokuvamile yenziwa nge-carbide nensimbi engagqwali ukuze kuqinisekiswe amandla nokugqoka ukumelana nendawo yokuvala.

2.2.Amandla esakhiwo

I-Butterfly valve Endaweni enengcindezi ephezulu, i-valve yovemvane idinga ukumelana nokucindezela okukhulu, ngakho-ke impahla kanye nesakhiwo se-valve uvemvane kumele kube namandla anele kanye nokuqina.Isakhiwo se-valve uvemvane ngokuvamile sihlanganisa umzimba we-valve, i-valve plate, i-valve stem, isihlalo se-valve nezinye izingxenye.Amandla anganele anoma iyiphi yalezi zingxenye angabangela ukuthi i-valve uvemvane ihluleke ngaphansi kwengcindezi ephezulu.Ngakho-ke, kuyadingeka ukucabangela ithonya lokucindezela lapho uklama isakhiwo se-valve butterfly futhi wamukele izinto ezinengqondo kanye namafomu esakhiwo.

2.3.Ukusebenza kwe-valve

Indawo enengcindezi ephezulu ingase ithinte i-torque ye-valve uvemvane, futhi i-valve uvemvane ingase idinge amandla amakhulu okusebenza ukuze ivule noma ivale.Ngakho-ke, uma i-valve ye-butterfly ingaphansi kwengcindezi ephezulu, kungcono ukukhetha ugesi, i-pneumatic namanye ama-actuator.

2.4.Ingozi yokuvuza

Ezimweni ezinengcindezi ephezulu, ingozi yokuvuza iyanda.Ngisho nokuvuza okuncane kungaholela ekumoshweni kwamandla nasezingozini zokuphepha.Ngakho-ke, kuyadingeka ukuqinisekisa ukuthi i-valve ye-butterfly inomsebenzi omuhle wokuvala ezindaweni ezinengcindezi ephezulu ukunciphisa ingozi yokuvuza.

2.5.Ukumelana nokugeleza okumaphakathi

Ukumelana nokugeleza kuyinkomba ebalulekile yokusebenza kwe-valve.Kuyini ukumelana nokugeleza?Isho ukumelana okutholwa uketshezi oludlula kuvalvu.Ngaphansi kwengcindezi ephezulu, ingcindezi ye-medium ku-valve plate iyakhuphuka, idinga ukuthi i-valve uvemvane ibe namandla okugeleza aphezulu.Ngalesi sikhathi, i-valve butterfly idinga ukuthuthukisa ukusebenza kokugeleza nokunciphisa ukumelana nokugeleza.

Ngokuvamile, umthelela wokushisa nokucindezela ekusebenzeni kwe-butterfly valve kunezimo eziningi, okuhlanganisa ukusebenza kokuvalwa, amandla esakhiwo, ukusebenza kwe-valve butterfly, njll. Ukuze kuqinisekiswe ukuthi i-valve butterfly ingasebenza ngokujwayelekile ngaphansi kwezimo ezahlukene zokusebenza, kuyadingeka ukukhetha. izinto ezifanele, ukwakheka kwesakhiwo kanye nokubeka uphawu, futhi uthathe izinyathelo ezihambisanayo zokubhekana nokushintsha kwezinga lokushisa nengcindezi.