1. Iyini ivalvu yebhabhathane ye-EN593?

I-valve ye-butterfly ye-EN593 ibhekisela ku-valve ye-butterfly yensimbi eklanywe futhi yakhiqizwa ngokuhambisana ne-BS EN 593:2017 standard, enesihloko esithi “Industrial Valves - General Metal Butterfly Valves.” Le standard ishicilelwe yi-British Standards Institution (BSI) futhi ihambisana nezindinganiso zaseYurophu (EN), enikeza uhlaka oluphelele lokuklama, izinto zokwakha, ubukhulu, ukuhlolwa, kanye nokusebenza kwama-butterfly valve.

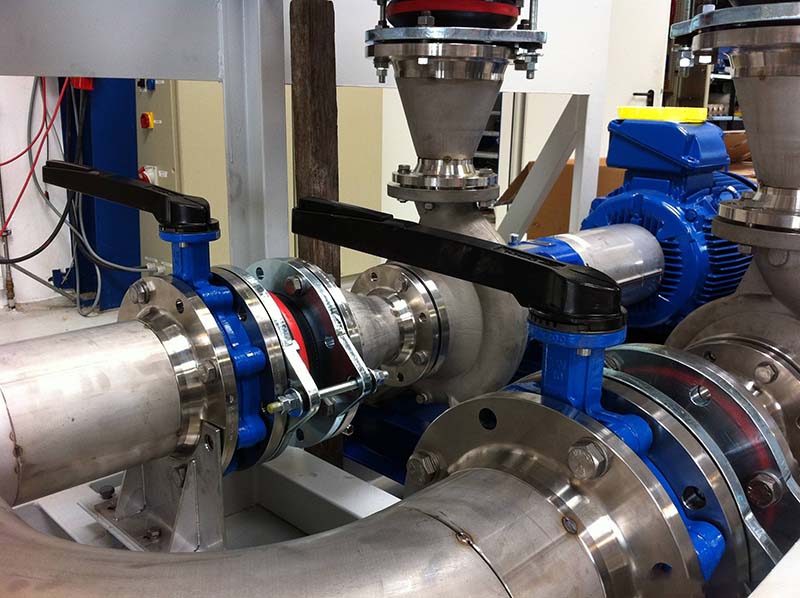

Amavalvu e-butterfly e-EN593 abonakala ngemizimba yawo yamavalvu ensimbi kanye nezindlela ezahlukahlukene zokuxhuma, njengohlobo lwe-wafer, uhlobo lwe-lug, noma olune-double-flanged. Lawa mavalvu e-butterfly angasebenza ngaphansi kwezimo ezahlukene zokucindezela kanye nokushisa. Leli zinga liqinisekisa ukuthi amavalvu ahlangabezana nezidingo eziqinile zokuphepha, ukuqina, ukuhambisana, kanye nokuthembeka.

2. Izici Eziyinhloko Zama-EN593 Butterfly Valve

* Ukusebenza kokujika kwekota: Ama-valve e-Butterfly asebenza ngokujikeleza idiski ye-valve ngama-degree angu-90, okwenza kube lula ukulawula ukugeleza okusheshayo nokuphumelelayo.

* Umklamo ohlangene: Uma kuqhathaniswa nama-valve esango, ama-valve ebhola, noma ama-valve e-globe, ama-valve e-butterfly alula futhi ayonga isikhala, okwenza afaneleke kakhulu ekufakweni okunendawo encane.

* Ukuxhumeka okuhlukahlukene kwezinhlangothi: Kutholakala nge-wafer, i-lug, i-flange ephindwe kabili, i-flange eyodwa, noma imiklamo yohlobo lwe-U, ehambisana nezinhlelo ezahlukene zamapayipi.

* Ukumelana nokugqwala: Kwakhiwe ngezinto ezisezingeni eliphezulu ezingamelani nokugqwala ukuqinisekisa ukuqina ezindaweni ezigqwalayo.

* I-torque ephansi: Yakhelwe ukunciphisa izidingo ze-torque, ivumela ukuzenzekela ngama-actuator amancane kanye nokunciphisa izindleko.

* Ukuvalwa kwe-Zero-leakage: Ama-valve amaningi e-EN593 anezihlalo ezithambile ezinwebekayo noma izihlalo zensimbi, ahlinzeka ngokuvalwa okuqinile njengebhamuza ukuze kusebenze kahle.

3. BS EN 593:2017 Imininingwane Ejwayelekile

Kusukela ngo-2025, indinganiso ye-BS EN 593 yamukela inguqulo ka-2017. I-EN593 iyisiqondiso esiphelele sama-valve e-butterfly ensimbi, echaza izidingo ezincane zokuklama, izinto zokwakha, ubukhulu, kanye nokuhlolwa. Okulandelayo isingeniso esinemininingwane kokuqukethwe okuyinhloko kwale ndinganiso, okusekelwa idatha yemboni.

3.1. Ububanzi bendinganiso

I-BS EN 593:2017 isebenza kuma-valve e-metal butterfly ngezinhloso ezijwayelekile, okuhlanganisa ukuhlukaniswa, ukulawulwa, noma ukulawulwa kokugeleza koketshezi. Ihlanganisa izinhlobo ezahlukene zama-valve ngokuxhumeka kokuphela kwamapayipi, njenge:

* Uhlobo lwe-Wafer: Iboshwe phakathi kwama-flange amabili, inesakhiwo esincane kanye nomklamo olula.

* Uhlobo lwe-Lug: Inezimbobo zokufaka ezinezintambo, ezifanele ukusetshenziswa emaphethelweni epayipi.

* I-Double-flanged: Iqukethe ama-flange ahlanganisiwe, aboshwe ngqo kuma-flange epayipi.

* I-single-flanged: Iqukethe ama-flange ahlanganisiwe eduze kwe-axis ephakathi yomzimba we-valve.

* Uhlobo lwe-U: Uhlobo olukhethekile lwevalvu yohlobo lwe-wafer oluneziphetho ezimbili ze-flange kanye nobukhulu obuncane bokubhekana ubuso nobuso.

3.2. Ububanzi Bokucindezela Nobukhulu

I-BS EN 593:2017 icacisa ububanzi bokucindezela nobukhulu bama-valve e-butterfly:

* Izilinganiso zokucindezela:

- I-PN 2.5, i-PN 6, i-PN 10, i-PN 16, i-PN 25, i-PN 40, i-PN 63, i-PN 100, i-PN 160 (izilinganiso zokucindezela zaseYurophu).

- Isigaba 150, Isigaba 300, Isigaba 600, Isigaba 900 (izilinganiso zengcindezi ye-ASME).

* Ububanzi besayizi:

- DN 20 kuya ku-DN 4000 (ububanzi obujwayelekile, cishe amasentimitha angu-3/4 kuya ku-160).

3.3. Izidingo Zokuklama Nokukhiqiza

Leli zinga lichaza izindlela ezithile zokuklama ukuqinisekisa ukuthembeka nokusebenza kahle kwevalvu:

* Izinto zomzimba wevalvu: Amavalvu kumele akhiqizwe ngezinto zensimbi ezifana nensimbi ethambile, insimbi yekhabhoni (ASTM A216 WCB), insimbi engagqwali (ASTM A351 CF8/CF8M), noma ithusi le-aluminium (C95800).

* Umklamo wediski yevalvu: Idiski yevalvu ingaba phakathi nendawo noma ibe yi-eccentric (i-offset ukuze kuncishiswe ukuguguleka kwesihlalo kanye ne-torque).

* Izinto zesihlalo sevalvu: Izihlalo zevalvu zingenziwa ngezinto ezinwebekayo (njengerabha noma i-PTFE) noma izinto zensimbi, kuye ngokuthi zisetshenziswa kanjani. Izihlalo ezinwebekayo zinikeza ukuvala okungenawo amanzi, kanti izihlalo zensimbi kumele futhi zimelane namazinga okushisa aphezulu kanye nokugqwala ngaphezu kokufeza ukuvuza okungenawo amanzi.

* Ubukhulu bobuso nobuso: Kumelwe kuhambisane nezindinganiso ze-EN 558-1 noma ze-ISO 5752 ukuqinisekisa ukuhambisana nezinhlelo zamapayipi.

* Ubukhulu be-Flange: Iyahambisana nezindinganiso ezifana ne-EN 1092-2 (PN10/PN16), ANSI B16.1, ASME B16.5, noma i-BS 10 Table D/E, kuye ngohlobo lwe-valve.

* I-Actuator: Ama-valve angasetshenziswa ngesandla (ngesibambo noma nge-gearbox) noma asetshenziswe ngokuzenzakalelayo (i-actuator yomoya, kagesi, noma ye-hydraulic). I-flange ephezulu kumele ihambisane nezindinganiso ze-ISO 5211 ukuze kuvunyelwe ukufakwa kwe-actuator ejwayelekile.

3.4. Ukuhlolwa Nokuhlolwa

Ukuqinisekisa ikhwalithi nokusebenza, i-BS EN 593:2017 idinga ukuhlolwa okuqinile:

* Ukuhlolwa komfutho we-hydraulic: Kuqinisekisa ukuthi i-valve ayivuzi uma icindezelwe ngendlela ethile.

* Ukuhlolwa kokusebenza: Kuqinisekisa ukusebenza okubushelelezi kanye ne-torque efanele ngaphansi kwezimo ezilingisiwe.

* Ukuhlolwa Kokuvuza: Qinisekisa ukuvalwa kwesihlalo se-valve esinwebekayo okuqinile ngokwezindinganiso ze-EN 12266-1 noma ze-API 598.

* Isitifiketi Sokuhlola: Umenzi kumele ahlinzeke ngemibiko yokuhlola nokuhlola ukuqinisekisa ukuhambisana nezindinganiso.

3.5. Ukusetshenziswa kwama-EN593 Butterfly Valve

* Ukwelashwa Kwamanzi: Lawula futhi uhlukanise ukugeleza kwamanzi ahlanzekile ahlukahlukene, amanzi olwandle, noma amanzi angcolile. Izinto zokwakha kanye nezingubo ezingamelani nokugqwala kuzenza zifanelekele izindawo ezinolaka.

* Izimboni Zamakhemikhali Namakhemikhali: Ukuphatha uketshezi oluqothulayo olufana nama-asidi, ama-alkali, kanye nezinyibilikisi, kuzuza ezintweni ezifana nezihlalo ze-PTFE kanye nama-valve disc ane-PFA.

* Uwoyela negesi: Ukuphatha uketshezi olunomfutho ophezulu, olushisa kakhulu emapayipini, ezindaweni zokuhluza, kanye nasezinkundleni zasogwini. Umklamo we-double-offset uyathandwa ngenxa yokuqina kwawo ngaphansi kwalezi zimo.

* Izinhlelo ze-HVAC: Ukulawula ukugeleza komoya, amanzi, noma i-refrigerant ezinhlelweni zokushisa nokupholisa.

* Ukukhiqizwa kukagesi: Ukulawula umusi, amanzi apholile, noma olunye uketshezi ezitshalweni zikagesi.

* Izimboni zokudla nezokwelapha: Ukusebenzisa izinto ezihambisana ne-FDA (njenge-PTFE kanye ne-WRA-certified EPDM) ukuqinisekisa ukusebenza okungenakungcola kanye nokuhlangabezana nezindinganiso zokuhlanzeka.

3.6. Ukugcinwa Nokuhlolwa

Ukuqinisekisa ukusebenza kwesikhathi eside, ama-valve e-butterfly e-EN593 adinga ukulungiswa njalo:

* Imvamisa yokuhlola: Hlola njalo ezinyangeni eziyisithupha kuya onyakeni owodwa ukuze uthole izinkinga zokuguguleka, ukugqwala, noma ukusebenza.

* Ukugcotshwa: Nciphisa ukungqubuzana futhi wandise isikhathi sokuphila kwevalvu.

* Ukuhlolwa Kwesihlalo Sevalvu Nophawu: Qinisekisa ubuqotho bezihlalo zevalvu ezinwebekayo noma zensimbi ukuvimbela ukuvuza.

* Ukulungiswa kwe-Actuator: Qinisekisa ukuthi ama-actuator asebenzisa umoya noma kagesi awanazo izinsalela futhi asebenza ngendlela evamile.

4. Ukuqhathaniswa namanye amazinga e-API 609

Nakuba i-BS EN 593 isebenza ekusetshenzisweni okuvamile kwezimboni, ihlukile ku-API 609 standard, eyenzelwe ngqo ukusetshenziswa kukawoyela negesi. Umehluko obalulekile uhlanganisa:

* Ukugxila kokusetshenziswa: I-API 609 igxile ezindaweni zikawoyela negesi, kuyilapho i-BS EN 593 ihlanganisa uhla olubanzi lwezimboni, okuhlanganisa ukwelashwa kwamanzi kanye nokukhiqiza okuvamile.

* Izilinganiso zokucindezela: I-API 609 ivame ukumboza iKlasi 150 kuya kuKlasi 2500, kuyilapho i-BS EN 593 ihlanganisa i-PN 2.5 kuya ku-PN 160 kanye neKlasi 150 kuya kuKlasi 900.

* Umklamo: I-API 609 igcizelela izinto ezingagqwali ukuze zikwazi ukumelana nezimo ezinzima, kuyilapho i-BS EN 593 ivumela ukukhethwa kwezinto eziguquguqukayo kakhudlwana.

* Ukuhlolwa: Zombili izindinganiso zidinga ukuhlolwa okuqinile, kodwa i-API 609 ifaka izidingo ezengeziwe zomklamo ongashi, okubaluleke kakhulu ekusetshenzisweni kukawoyela negesi.

5. Isiphetho

| Isici | Izici Eziyinhloko Ezichazwe yi-EN 593 |

| Uhlobo lwe-Valve | Amavalvu ebhabhathane ensimbi |

| Ukusebenza | Isandla, igiya, umoya, ugesi |

| Ubukhulu Bobuso Nobuso | Njengoba kuchazwe ku-EN 558 Series 20 (i-wafer/i-lug) noma uchungechunge 13/14 (olunama-flanged) |

| Isilinganiso Sokucindezela | Ngokuvamile i-PN 6, i-PN 10, i-PN 16 (ingahluka) |

| Izinga Lokushisa Lomklamo | Kuncike ezintweni ezisetshenziswayo |

| Ukuhambisana kwe-Flange | I-EN 1092-1 (ama-flange e-PN), i-ISO 7005 |

| Amazinga Okuhlola | I-EN 12266-1 yokuhlolwa kokucindezela nokuvuza |

Izinga le-BS EN 593:2017 linikeza uhlaka oluqinile lokuklama, ukukhiqiza, nokuhlola ama-valve e-butterfly ensimbi, okuqinisekisa ukuthembeka kwawo, ukuphepha, kanye nokusebenza kwawo kuzo zonke izinhlelo zokusebenza. Ngokunamathela ezidingweni zezinga lokulinganisa ingcindezi, ububanzi bosayizi, izinto zokwakha, kanye nokuhlolwa, abakhiqizi bangakhiqiza ama-valve ahlangabezana nezilinganiso zekhwalithi yomhlaba wonke.

Kungakhathaliseki ukuthi udinga amavalvu ebhabhathane anohlobo lwe-wafer, uhlobo lwe-lug, noma olunezinhlangothi ezimbili, ukuhambisana nendinganiso ye-EN 593 kuqinisekisa ukuhlanganiswa okungenamthungo, ukuqina, kanye nokulawulwa koketshezi okuphumelelayo.