A i-butterfly valve egcwele ngokugcweleihlanganisa isakhiwo esigcwele umugqa ngaphakathi komzimba we-valve. Lo mklamo uklanyelwe ngokukhethekile izinhlelo zokusebenza ezimelana nokugqwala.

"Umugqa ogcwele" kusho ukuthi akuyona nje i-disc evalelwe ngokuphelele, kodwa futhi isihlalo sivalwe ngokuphelele, siqinisekisa ukuhlukaniswa okuphelele phakathi kwabezindaba kanye nensimbi.

1. Izinto ezimbili ezivamile zolwelwesi

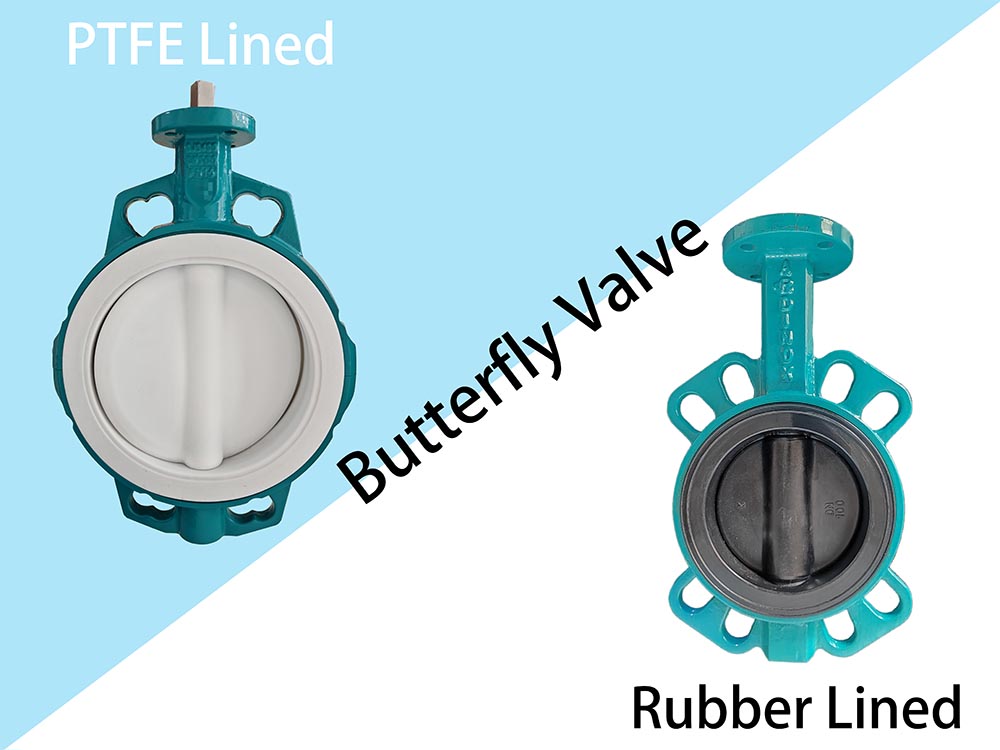

a. I-PTFE (i-polytetrafluoroethylene, i-perfluoroplastic) i-valve butterfly yomugqa

b. I-valve ye-butterfly yomugqa werabha

| Uhlobo Lwezinto: | I-Polytetrafluoroethylene (PTFE) intambo | Ulayini lwerabha (isb, EPDM, Viton, NBR) |

| Inqubo ye-Lining | I-PTFE/PFA encibilikisiwe ithululelwa emgodini we-dovetail emzimbeni/idiski, kuzuzwe ibhondi engenamthungo. | Ibe isivuzwa ngokuqondile (iphulukiswe ukushisa) phezu kwensimbi, yenze uphawu oluqinile, olubalulekile. |

| Izici ezibalulekile | - Ukumelana nokugqwala okuhle kakhulu (ukumelana cishe nawo wonke ama-asidi, izisekelo, nezinyibilikisi zemvelo) - Ukumelana nokushisa okuphezulu (ukushisa okusebenzayo okuqhubekayo kufika ku-180°C) - I-coefficient ephansi ye-friction kanye nezakhiwo ezinganamathele, ezifanele imidiya yokuhlanzeka okuphezulu

| - Ukunwebeka okuhle kakhulu nokusebenza okuhle kakhulu kokubeka uphawu (kulula ukufeza ukuvuza kwe-zero) - Izindleko eziphansi nokumelana nokugqokwa okuhle kwemidiya engagqwali - Ukumelana nokushisa okuphansi (imvamisa -20°C kuya ku-180°C, kuye ngohlobo lwerabha)

|

| Imidiya Esebenzayo | Ama-asidi aqinile (njenge-sulfuric acid ne-hydrochloric acid), izisekelo eziqinile, izinyibilikisi eziphilayo, uketshezi oluhlanzekile kakhulu. | amanzi, amanzi angcolile, ama-asidi abuthakathaka nezisekelo, ama-slurries, nemidiya yezinga lokudla |

| Izicelo Ezijwayelekile | Imboni Yamakhemikhali (ukudluliswa kwe-asidi ne-alkali), Imboni Yemithi (ukudluliswa kwezinto ezihlanzekile kakhulu) | Ukuhlanza Amanzi (ukuhlanza amanzi angcolile, amanzi ompompi), Amasistimu we-HVAC, Imboni Yokudla Nesiphuzo, Imayini (ukudlulisa okudaka) |

2. Izinyathelo ezinemininingwane zenqubo ye-PTFE-lined Valve Discs

2.1 Ukulungiswa Kwediski Yensimbi

a.. Sakaza noma mshini umgogodla wediski lensimbi, uqinisekise ukuthi indawo engaphezulu ihlanzekile futhi ayinawo uwoyela nokungcoliswa.

b.. Sika ama-grooves (umumo we-dovetail) endaweni ewumgogodla ukuze unikeze amaphuzu okubamba umjovo we-PTFE futhi uvimbele ukuthi ungawi.

2.2 I-PTFE Powder Molding and Preforming

a. Faka inani elibalwe ngokucophelela le-PTFE powder (noma i-premix) esibunjeni, faka i-valve butterfly core, bese wengeza i-PTFE powder.

b. Kancane kancane faka i-vacuum (i-exhaust) kanye nokucindezela (ukucindezela noma ukucindezela kwe-isostatic) ukuze wenze umbungu oluhlaza. Ukubunjwa kwe-Isostatic: Gxilisa isikhunta emanzini futhi usebenzise ukucindezela okufanayo kuzo zonke izinhlangothi (i-pressure conduction yamanzi) ukuze uqinisekise isakhiwo esifanayo nesiminyene (i-porosity iphansi njenge-<1%).

2.3 Ukugeza kanye nokuhlanza

a. Faka i-embryo eluhlaza kuhhavini bese ushisa ku-380 ° C amahora angu-5-24 (kancane kancane ukwandisa izinga lokushisa ukuze ugweme ukuqhekeka).

b. Kuphole kancane kuya ekamelweni lokushisa ukuvumela i-PTFE ukuthi icwebezele futhi ixube nomongo wensimbi, yenze ukunamathela okungenamthungo (ukuqina kulawulwa kube ngu-3-10mm, kulungiswe ngokuvumelana nezimo ze-vacuum).

2.4 Ukukhanda nokuqeda:

Sebenzisa i-lathe noma umshini we-CNC umshini wamadayimitha angaphakathi nangaphandle ukuze uqinisekise idiski nesihlalo silingana kahle (ukubekezelelana kuqinile, isb, ±0.01mm).

2.5 Ukuhlolwa Kwekhwalithi Nokuhlolwa:

a. Ukukala Ubukhulu: Qinisekisa ulayini obuncane obungu-3mm, noma ngendlela oyifisayo.

b. Ukuhlolwa kwe-Spark: 35,000 volts wokuhlolwa kokuqina (akukho ukwehlukana okubonisa ukwamukela).

c. Ukuhlolwa kweVacuum/Amandla: Kulingisa izimo zokusebenza ukuze kuhlolwe ukuvuza nokungena (ngokuhambisana ne-EN 12266-1 noma i-API 598).

d. Ukuhlolwa Kokusebenza (ongakukhetha): Ukumelana nobuso <10⁶Ω kwezinhlelo zokusebenza ezivikela ukuqhuma.

3. Izinyathelo Eziningiliziwe Zenqubo Yamadiski anemigqa ye-EPDM

3.1 Ukulungiswa Kwediski Yensimbi

a. Sakaza noma mshini indikimba yensimbi ukuze uqinisekise indawo ehlanzekile, engagqwali.

b. Isihlabathi noma ukucisha amakhemikhali indawo engaphezulu (ubukhulu Ra 3-6μm) ukukhuthaza ukunamathela kwe-EPDM.

3.2 Isicelo seNhlangano ye-EPDM kanye nokwenza kuqala

Inhlanganisela ye-EPDM engapholisiwe (ishidi noma uketshezi) ifakwa esikhunjeni, igoqe umgogodla wensimbi. Usebenzisa ukubumba kokucindezelwa noma ukuthulula, ukusabalalisa ngokulinganayo inhlanganisela phezu kwendawo yediski ye-valve ukuze wenze umzimba oluhlaza. Gcina ukujiya okungu-2-5 mm, uqinisekisa ukumbozwa emaphethelweni ediski.

3.3 Ukwelapha

Umzimba oluhlaza ufakwa ku-autoclave futhi ushiswe nge-steam noma umoya oshisayo (150-180 ° C, ingcindezi> 700 psi, amahora angu-1-4).

Inqubo yokwelapha ihlanganisa izixhumanisi futhi yelapha i-EPDM, ihlanganiswe ngamakhemikhali nangomshini kumongo wensimbi ukuze kwakheke umugqa ongenamthungo, wocezu olulodwa. Khulisa izinga lokushisa kancane ukuze ugweme amabhamuza omoya noma imifantu.

3.4 Ukuqeda Ngomshini

Ngemva kokupholisa, sika amaphethelo angaphakathi nangaphandle usebenzisa i-CNC lathe ukuze uqinisekise idiski nesihlalo silingana kahle (ukubekezelelana ±0.05 mm). Khipha irabha eyeqile bese uhlola iphrofayili enqenqemeni (i-Ni-Cu coating ingakhethwa ukuze kuthuthukiswe ukumelana nokugqokwa).

3.5 Ukuhlolwa Kwekhwalithi Nokuhlolwa

a. Ukuhlolwa Kokuqina Nokunamathela: Ukulinganisa ukushuba kwe-Ultrasonic (ubuncane be-2mm); Ukuhlolwa kwe-Tensile (amandla e-peel>10 N/cm).

b. Ukuqinisekiswa Kokusebenza: Ukuhlolwa Kwe-Bubble Tight Seal (okujwayelekile kwe-API 598); I-Pressure/Vacuum Test (PN10-16, ukumelana nengcindezi engemihle).

c. Ukuhlolwa Kwamakhemikhali / Ukuguga: Ukucwiliswa ku-asidi nemidiya ye-alkaline, ukuhlola ukwanda <5%; Ukuguga okunezinga lokushisa eliphezulu (120°C, 72h).

4. Umhlahlandlela Wokukhetha

I-PTFE linings ifanele imidiya egqwala kakhulu (njengama-asidi, ama-alkali, nezinyibilikisi), kuyilapho amalayini e-EPDM afanelekela imidiya esekwe emanzini, ethambile (njengamanzi nama-asidi axubile). Beka kuqala ukuhambisana kwamakhemikhali, izinga lokushisa, ingcindezi, kanye nezindleko zokuthuthukisa uhlelo lokusebenza. I-Zhongfa Valve ikhiqiza ama-valve ovemvane anemigqa ephelele ene-wafer, flange, nezinketho zamalug. Sicela usithinte nganoma yimiphi imibuzo.

Isikhathi sokuthumela: Oct-28-2025