Amavalvu ezimvemvane ezivikela umlilo avame kakhulu ekwakheni izinhlelo zokulwa nomlilo.

Zisetshenziswa kakhulu ukulawula ukugeleza kwamanzi. Zivuleka futhi zivaleke ngokushesha. Zincane futhi kulula ukuzifaka.

Uma kuqhathaniswa nama-valve esango noma ama-valve e-globe, ama-valve e-butterfly adinga amandla amancane okusebenza. Lokhu kuwenza afaneleke kakhulu kumapayipi amakhulu.

Uvame ukuzithola emapayipini amakhulu ezinhlelo zamanzi omlilo zangaphakathi, izinhlelo zokufafaza ezizenzakalelayo, izindawo zokufaka amaphampu omlilo, izinhlelo zokuphakelwa kwamanzi ezihlukaniswe ngezindawo, kanye nezindawo zomlilo zangaphandle.

Zikhona yonke indawo ezinhlelweni zomlilo. Ngenxa yalokhu, zivame ukuthathwa kalula.

1. Yini Eyenza I-Butterfly Valve “Ibanga Lokuvikela Umlilo”

1.1 Incazelo yeValvu Yebhathaneli Yokuvikela Umlilo.

Amavalvu ebhabhathane avikela umlilo avame ukubizwa ngokuthi amavalvu ebhabhathane esignali yomlilo noma amavalvu omlilo anikezelwe.

Ivalvu yebhabhathane yokuvikela umlilo ayichazwa ngokubukeka noma igama layo.

Kubhekisele ku-valve yebhabhathane efanele ukusetshenziswa ezinhlelweni zokulwa nomlilo. Isetshenziswa kakhulu ukulawula ukugeleza kwamanzi emipayipini ye-hydrant noma ye-sprinkler.

Umehluko oyinhloko kusuka ku-valve evamile ye-butterfly yile:

Ingathumela izimpawu zokuvula noma zokuvala ngesikhathi sangempela esikhungweni sokulawula umlilo.

Ngaphezu kwalokho, ivalvu yebhabhathane yokuvikela umlilo kumele isebenze ngokuthembekile ngaphansi kwezimo ezimbi kakhulu zesistimu yomlilo, okuhlanganisa:

*Ingcindezi yesikhathi eside engaguquki

*Umfutho wegazi ukhuphuka ngokuzumayo lapho kuqala iphampu yomlilo

*Isando samanzi ngesikhathi sokusebenza kwe-valve noma ukushintsha uhlelo

*Ukusebenza okuthembekile ezimweni eziphuthumayo

1.2 Kungani Kusetshenziswa Ama-Butterfly Valve Ezinhlelweni Zomlilo?

Ukusebenza kwamadigri angu-90 ukuze kuphendulwe ngokushesha

Ukumelana okuphansi kwediski kanye nokulahlekelwa kwengcindezi okulawulwayo

Kungcono kakhulu kunezivalo zesango ngobukhulu obukhulu

2. Izinhlobo Ezivamile Nezinto Zokusebenza Zamavalvu E-Butterfly Okuvikela Umlilo

Ama-valve amaningi okuvikela umlilo avikela uhlobo olunemiphetho noma uhlobo olune-flanged.

Zihlonyiswe ngezibonakaliso zesikhundla. Isimo sokuvula nokuvala singathunyelwa egumbini lokulawula umlilo.

2.1 Izinhlobo Zokuxhumana

2.1.1 Ivalvu Yebhabhathane Enemivimbo Emikhulu

Imigoqo iyasikwa emaphethelweni epayipi bese ixhunywa ngama-coupling.

Ukufakwa kuyashesha futhi akudingeki ukushisela.

I-valve yebhabhathane yohlobo lwe-Groovesifanele izakhiwo ezintsha kanye nokulungiswa kwezindawo.

Ngaphezu kwama-80% ezinhlelo zomlilo zisebenzisa lolu hlobo.

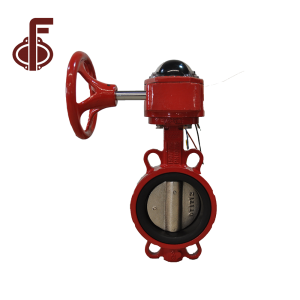

2.1.2 I-Wafer Butterfly Valve

Iivalvu yohlobo lwe-waferUmzimba awunazo iziphambano futhi uboshwe ngqo phakathi kweziphambano zamapayipi amabili.

Incane kakhulu futhi ilula kakhulu, kodwa idinga ukulungiswa okunembile ngesikhathi sokufakwa.

2.1.3 I-Flanged Butterfly Valve

Zombili iziphetho zineziphambano futhi ziqiniswe ngamabhawodi.

Ukuvala kuthembekile futhi ukulungiswa kulula.

Lolu hlobo luvame ukusetshenziselwa amapayipi acindezelayo aphezulu noma amakhulu.

2.2 Izinhlobo Zokuvala

2.2.1 I-Soft Seat Butterfly Valve

Kusetshenziswa ukuvala irabha. Ukusebenza kokuvala okuqinile.

Kufanelekela amanzi ahlanzekile ekushiseni okujwayelekile.

2.2.2 Ivalvu Yesibhakabhaka Ehleli Ngensimbi

Insimbi ibe yinsimbiukuvala. Kungcono uma ucindezelekile kakhulu.

Ifanele amanzi angase abe nokungcola.

Ezintweni zokwakha, umzimba we-valve uvame ukuba yinsimbi ethambile ene-epoxy coating yokuvikela ukugqwala.

Idiski iyinsimbi ethambile ene-nickel coating noma insimbi engagqwali.

Isiqu siyinsimbi engagqwali.

Amanzi omlilo avame ukuhlala engashintshi isikhathi eside. Ingozi yokugqwala iphezulu.

Lezi zinto zikhethwa ukuze zisebenze isikhathi eside.

3. Izilinganiso Eziyinhloko Zokucindezela Ezinhlelweni Zokuvikela Umlilo

3.1 Ukuphakama Kwesifutho Esisekelwe Embonweni Ngaphansi Kwengcindezi

Kumaphrojekthi amaningi omlilo, i-PN16 iyisilinganiso sokucindezela okuzenzakalelayo.

Ngokwe-GB 50974 ejwayelekile yaseShayina – Ikhodi Yokuklama Izinhlelo Zokuphakelwa Kwamanzi Nokuhlinzekwa Kwamanzi Omlilo, ingcindezi yokusebenza kwezinhlelo zomlilo zangaphakathi ivame ukuba phakathi kuka-1.0 MPa no-1.6 MPa.

Ezakhiweni eziphakeme noma ezindaweni ezinkulu, ingcindezi ingaba phezulu.

Kodwa-ke, i-PN16 isivele ihlanganisa izakhiwo eziningi ezivamile.

Abantu abaningi bayabuza ukuthi amanzi aphezulu angafafaza kangakanani ngaphansi kwalolu xinzelelo.

Uma sithatha i-nozzle yepayipi lomlilo njengesibonelo, ngaphansi kwengcindezi ye-PN16, amanzi angafinyelela cishe amamitha ayi-163 ngokuma.

Leli nani libalwa kusetshenziswa ifomula:

h = P / (ρ × g)

Kuphi:

P = 1.6 × 10⁶ Pa

ρ (ubuningi bamanzi) ≈ 1000 kg/m³

g ≈ 9.81 m/s²

Umphumela obaliwe:

h ≈ 163 m

Ezimweni zangempela, ukumelana nomlomo, ukungqubuzana komoya, kanye nokulahlekelwa yipayipi kunciphisa ukuphakama.

Ukuphakama kwangempela kwesifutho ngokuvamile kungama-140–150 amamitha.

Lokhu kwanele ezakhiweni eziningi, njengezindlu zokuhlala ezinde kanye nezitolo ezinkulu.

3.2 Ukuphakama Kwangempela Kokufutha Emsebenzini Wobunjiniyela

Ezinhlelweni zomlilo, ukucindezela akuyona into ecatshangelwayo.

Kuhlobene ngqo nokuphakama kwesakhiwo.

Ngemva kokucabangela ukulahlekelwa yipayipi, imingcele yokuphepha, kanye nokushintshashintsha kwengcindezi okubangelwa ukuqala nokuma kwepompo, amanani alandelayo avame ukwamukelwa:

| Isimo | Ukuphakama Kwangempela |

| Umkhawulo wethiyori | 163 m |

| Isimo sobunjiniyela esifanele | 110–130 m |

| Isimo sendawo esijwayelekile | 80–100 m |

| I-Sprinkler/i-spray nozzle | 50–80 m |

Ngenxa yalokhu, i-PN16 iba yisinqumo esiphephile nesingabizi kakhulu.

3.3 Izilinganiso Ezivamile Zokucindezela Emisebenzini Yomlilo

Izinhlelo zokufaka amanzi omlilo zangaphakathi → PN16

Izinhlelo zokufafaza ezizenzakalelayo → PN16

Amapayipi amakhulu omlilo angaphandle → PN16 noma ngaphezulu

Izintambo zokukhipha iphampu yomlilo → PN20 / PN25 kwamanye amaphrojekthi

Uma isilinganiso sokucindezela siphansi kune-PN16,

uhlelo lungase lungabi nesilinganiso esanele sokuphepha ngesikhathi sezimo eziphuthumayo.

Isikhathi sokuthunyelwe: Jan-23-2026