Amavalvu ovemvane aqinileziwuhlobo olusetshenziswa kakhulu lwevaluve uvemvane kumapayipi ezimboni. Basebenzisa izinto ezinwebekayo njengenjoloba njengendawo yokuvala, ethembele "ekuqiniseni izinto ezibonakalayo" kanye "nokucindezela kwesakhiwo" ukuze bathole ukusebenza kokuvala.

Lesi sihloko akwethuli nje kuphela isakhiwo, ukusetshenziswa, nezinto zokwakha, kodwa futhi sihlaziya kusuka olwazini olujwayelekile kuya ekujuleni komqondo.

1. Ukuqonda Okuyisisekelo Kwamavalvu Ovemvane Aqinile (Incazelo emfushane)

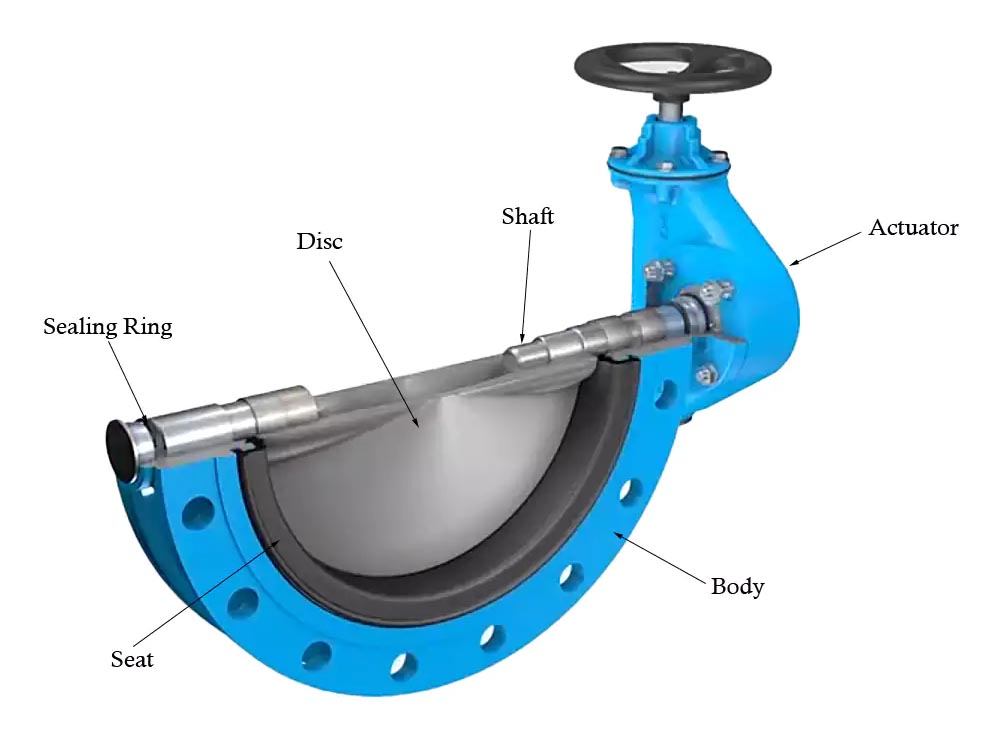

1.1 Isakhiwo Esiyisisekelo

Umzimba weValve:Ngokuvamile uhlobo lwe-wafer, uhlobo lwe-lug, noma uhlobo oluvulekile.

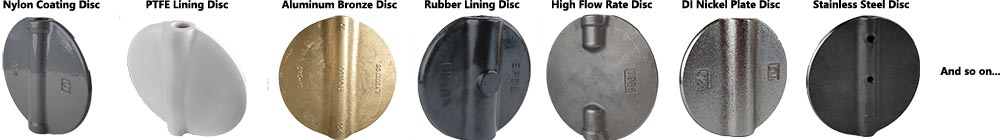

I-Valve Disc:Ipuleti lensimbi eliyindilinga elicindezela isihlalo senjoloba lapho livaliwe ukuze lidale uphawu.

Isihlalo seValve:Yenziwe ngezinto ezinwebekayo ezifana ne-NBR/EPDM/PTFE/Rubber Lined, esebenza ngokuhlanganyela nediski ye-valve.

Isiqu se-valve:Ikakhulukazi isebenzisa i-single-shaft noma i-double-shaft design.

I-Actuator:Isibambo, igiya lezikelemu, ugesi, i-pneumatic, njll.

1.2 Izici Ezivamile

Izinga lokuvala ngokuvamile lizuza ukuvuza okunguziro.

Izindleko eziphansi kanye nohlu olubanzi lwezinhlelo zokusebenza.

Isetshenziswa kakhulu ezinhlelweni zengcindezi ephansi kuya emaphakathi njengamanzi, isimo somoya, i-HVAC, nezimboni zamakhemikhali alula.

2. Imibono Engelona iqiniso mayelana namaVave Evemvane Aqinile

2.1 Umnyombo wokuvalwa kwerabha ukuqina

Abantu abaningi bakholelwa ukuthi: "Izihlalo eziqinile zithembele ekuqineni kwenjoloba ukuze zivalwe."

Ingqikithi yeqiniso yokubekwa uphawu yile:

Umzimba we-valve + ibanga lesikhungo se-valve + ukujiya kwe-valve disc + indlela yokushumeka isihlalo se-valve

Ngokuhlangene dala "indawo yokucindezela elawulwayo".

Kalula nje:

Irabha ayikwazi ukuxega kakhulu noma iqine kakhulu; ithembela "kundawo yokucindezela yokuvala" elawulwa ngokunemba komshini.

Kungani lokhu kubalulekile?

Ukucindezela okunganele: Ukuvuza kwevalvu uma ivaliwe.

Ukucindezelwa ngokweqile: I-torque ephezulu kakhulu, ukuguga ngaphambi kwesikhathi kwerabha.

2.2 Ingabe umumo wediski ohleleke kakhudlwana uwonga amandla?

Ukubuka okuvamile: Amadiski e-valve alula anganciphisa ukulahlekelwa kwengcindezi.

Lokhu kuyiqiniso ngokombono "wemishini yoketshezi", kodwa akusebenzi ngokuphelele ekusetshenzisweni kwangempela kwe-Resilient Butterfly Valves.

Isizathu:

Umthombo oyinhloko wokulahlekelwa kwengcindezi kuma-valve ovemvane akukona ukuma kwe-valve disc, kodwa "umphumela we-micro-channel effect" obangelwa ukufinyezwa kwerabha yesihlalo se-valve. I-valve disc ukuba izacile kakhulu ingase yehluleke ukunikeza ingcindezi eyanele yokuxhumana, okungase kuholele emigqeni yokuvala engapheli nokuvuza.

I-valve disc streamlined ingabangela amaphuzu abukhali okucindezeleka ku-rubber, inciphise isikhathi sayo sokuphila.

Ngakho-ke, idizayini yamavalvu ovemvane ahlezi kahle ibeka phambili "ukuzinza komugqa wokuvala" kunokwelula.

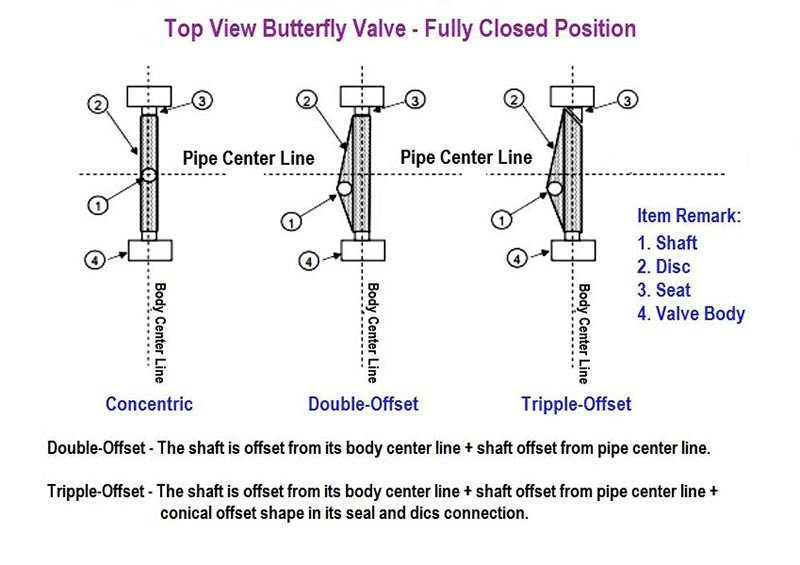

2.3 Amavalvu evemvane ahlezi kahle anesakhiwo esiphakathi nendawo

Kuvame ukushiwo ku-inthanethi ukuthi ama-valve butterfly eccentric kufanele asebenzise izigxivizo eziqinile zensimbi.

Nokho, ulwazi lobunjiniyela bomhlaba wangempela lubonisa ukuthi:

I-eccentricity ekabili ithuthukisa kakhulu impilo ye-Resilient Butterfly Valves.

Isizathu:

I-eccentricity ephindwe kabili: I-disc ye-valve ithinta kuphela irabha ngesikhathi sokugcina se-2-3 ° sokuvala, kunciphisa kakhulu ukungqubuzana.

I-torque ephansi, okuholela ekukhethweni kwe-actuator ukonga kakhulu.

2.4 Okucatshangelwayo okuyinhloko kwesihlalo senjoloba "igama lempahla"*

Abasebenzisi abaningi bagxila kuphela ku:

I-EPDM

I-NBR

I-Viton (FKM)

Kodwa okuthinta ngempela isikhathi sokuphila yilokhu:

2.4.1 Ukuqina kosebe:

Isibonelo, ubulukhuni be-Shore A be-EPDM akuyona indaba "yokuba ngcono kakhulu." Ngokuvamile, i-65-75 iyindawo yebhalansi efanelekile, ithola ukuvuza kwe-zero ngengcindezi ephansi (PN10-16).

Ithambile kakhulu: Itorque ephansi kodwa idabuka kalula. Ezindaweni eziphakeme zokucindezela okukhulu (>2 MPa) noma endaweni eneziyaluyalu, irabha ethambile icindezelwa ngokweqile, ibangele ukuwohloka kwe-extrusion. Ngaphezu kwalokho, amazinga okushisa aphezulu (>80°C) aphinde athambise irabha.

Kunzima kakhulu: Kunzima ukuvala, ikakhulukazi kumasistimu anengcindezi ephansi (<1 MPa), lapho irabha ingakwazi ukucindezelwa ngokwanele ukuze yakhe isixhumi esibonakalayo esingangenisi umoya, okuholela ekuvuzeni okuncane.

2.4.2 Izinga lokushisa le-Vulcanization kanye nesikhathi sokuphulukisa

Izinga lokushisa le-Vulcanization kanye nesikhathi sokuphulukisa kulawula ukuxhumanisa okuphambanayo kwamaketanga emolekyuli yerabha, okuthinta ngokuqondile ukuzinza kwesakhiwo senethiwekhi nokusebenza kwesikhathi eside. Ibanga elijwayelekile liyi-140-160°C, imizuzu engama-30-60. Amazinga okushisa aphezulu kakhulu noma aphansi kakhulu aholela ekwelapheni okungalingani kanye nokuguga okusheshayo. Inkampani yethu ivamise ukusebenzisa i-vulcanization yezigaba eziningi (pre-cureing at 140°C, kulandelwa ukuphulukiswa kwangemuva ku-150°C). 2.4.3 Isethi Yokucindezela

Isethi yokuminyanisa isho ingxenye yokuguquguquka okuhlala njalo irabha eba ngaphansi kwengcindezi eqhubekayo (imvamisa ukucindezelwa okungu-25% -50%, kuhlolwe ku-70°C/22h, ASTM D395) futhi ayikwazi ukululama ngokugcwele. Inani elifanele lesethi yokucindezelwa ngu-<20%. Leli nani "liyibhodlela" lokuvala i-valve isikhathi eside; ukucindezela okuphezulu kwesikhathi eside kuholela ezikhaleni ezihlala njalo, kwakha amaphuzu okuvuza.

2.4.4 Amandla Okuqina

A. Amandla Okuqina (imvamisa >10 MPa, ASTM D412) ingcindezi enkulu irabha engakwazi ukumelana nayo ngaphambi kokuphuka okuqinile, futhi ibalulekile ekuqineni kokuguga kanye nokungadabuki kwesihlalo sevalvu. Okuqukethwe kwerabha kanye nesilinganiso se-carbon black kunquma amandla e-valve eqinile.

Kumavalve ovemvane, imelana nokugunda ngonqenqema lwe-valve disc kanye nomthelela woketshezi.

2.4.5 Ingozi enkulu ecashile yamavalvu ovemvane ukuvuza.

Ezingozini zobunjiniyela, ukuvuza ngokuvamile akuyona inkinga enkulu, kodwa kunalokho ukwanda kwe-torque.

Okuholela ngempela ekuhlulekeni kwesistimu ukuthi:

Ukuqhuma okungazelelwe kwetorque → ukulimala kwegiya lezikelemu → ukukhubeka kwe-actuator → ukuminya kwevalvu

Kungani i-torque ikhuphuka ngokuzumayo?

- Ukunwetshwa kwezinga lokushisa eliphezulu kwesihlalo sevalvu

- Ukumuncwa kwamanzi kanye nokwandiswa kwerabha (ikakhulukazi i-EPDM yekhwalithi ephansi)

- Ukuguqulwa okuhlala njalo kwerabha ngenxa yokucindezela isikhathi eside

- Ukwakheka okungalungile kwegebe phakathi kwesiqu se-valve nediski ye-valve

- Isihlalo se-valve asigqekezwanga kahle ngemva kokushintshwa

Ngakho-ke, "ijika le-torque" liyinkomba ebaluleke kakhulu.

2.4.6 Ukunemba komshini wevalvu womzimba akubalulekile.

Abantu abaningi bakholelwa ngephutha ukuthi ukuvalwa kwama-valve ovemvane ahlezi ngokuthambile kuncike kakhulu kunjoloba, ngakho-ke izidingo zokunemba komshini womzimba we-valve aziphezulu.

Lokhu akulungile neze.

Ukunemba komzimba we-valve kuthinta:

Ukujula kwegroove yesihlalo sevalvu → ukuchezuka kokuminyanisa kokuvala, okubangela ukungaqondi kahle kahle phakathi nokuvula nokuvala.

Ukunwaya okunganele konqenqema lwegroove → ukunwaya ngesikhathi sokufakwa kwesihlalo sevalvu

Iphutha ebangeni elimaphakathi le-valve disc → ukuthintana okweqile okwenziwe kwasendaweni

2.4.7 Umnyombo "werabha egcwele/amavalve uvemvane anemigqa ye-PTFE" yidiski yevalvu.

Umongo werabha ngokugcwele noma isakhiwo esifakwe umugqa we-PTFE akukhona ukuba "nendawo enkulu ebonakala imelana nokugqwala," kodwa ukuvimbela okuphakathi nendawo ukuthi kungangeni kumashaneli amancane ngaphakathi komzimba wevalvu. Izinkinga eziningi ezinama-butterfly valves angabizi azibangelwa ikhwalithi yerabha ephansi, kodwa kunalokho:

"Igebe elimise okwe-wedge" lapho kuhlangana khona isihlalo sevalvu nomzimba alinakiwe ngendlela efanele.

Ukuguguleka koketshezi lwesikhathi eside → ama-microcracks → amabhamuza nerabha

Isinyathelo sokugcina ukwehluleka kwendawo kwesihlalo se-valve.

3. Kungani i-Resilient Butterfly Valves isetshenziswa emhlabeni wonke?

Ngaphandle kwezindleko eziphansi, izizathu ezintathu ezijulile yilezi:

3.1. Ukubekezelela amaphutha okuphezulu kakhulu

Uma kuqhathaniswa nezimpawu zensimbi, izigxivizo zenjoloba, ngenxa yokunwebeka kwazo okuhle kakhulu, zinokubekezelela okuqinile kokuphambuka kokufakwa kanye nokukhubazeka okuncane.

Ngisho namaphutha okwenziwa ngaphambili kwamapayipi, ukuchezuka kwe-flange, nokucindezela kwebhawodi okungalingani amuncwa ukunwebeka kwenjoloba (yebo, lokhu kunomkhawulo futhi akufuneki, futhi kuzodala umonakalo othile epayipini nevalvu ngokuhamba kwesikhathi).

3.2. Ukuvumelana nezimo okungcono kakhulu ekuguquguqukeni kwengcindezi yesistimu

Izigxivizo zenjoloba azikho "njenge-brittle" njengezimpawu zensimbi; banxephezela ngokuzenzakalelayo umugqa wokuvala ngesikhathi sokushintshashintsha kwengcindezi.

3.3. Izindleko eziphansi kakhulu zomjikelezo wempilo

Amavalvu ovemvane avalwe kanzima ahlala isikhathi eside, kodwa izindleko nezindleko ze-actuator ziphezulu.

Uma kuqhathaniswa, izindleko eziphelele zokutshala nokunakekela ama-Resilient Butterfly Valves zonga kakhulu.

4. Isiphetho

Inani leAmavavu Evemvane Aqinileakukhona nje "ukubekwa uphawu okuthambile"

Amavalvu ovemvane avaliwe angase abonakale elula, kodwa imikhiqizo emihle kakhulu isekelwa ingqondo eqinile yezinga lobunjiniyela, okuhlanganisa:

Idizayini enembile yendawo yokuminyanisa

Ukusebenza kwerabha elawulwayo

Ukumatanisa kwejiyomethri yomzimba we-valve nesiqu

Inqubo yokuhlanganisa isihlalo se-valve

Ukuphathwa kwe-torque

Ukuhlolwa komjikelezo wempilo

Lezi yizici ezibalulekile ezinquma ikhwalithi, hhayi "igama elibalulekile" kanye "nokwakheka kokubukeka".

QAPHELA:* IDATHA ibhekisa kule webhusayithi:https://zfavalves.com/blog/key-factors-that-determine-the-quality-of-soft-seal-butterfly-valves/

Isikhathi sokuthumela: Dec-09-2025