I-valve ye-butterfly idlula ezivivinyweni eziningi kusukela ekukhiqizeni kuya ekuthunyelweni ukuqinisekisa ikhwalithi nokuthembeka kwayo. Ukuhlolwa okuphelele kuhlanganisa izinto ezijwayelekile ezifana nezinto zokwakha, ukumbozwa, ukubukeka, irabha, ingcindezi, kanye nobukhulu, kanye nokusebenza kokuvala, ukubukeka, i-torque, ubulukhuni, ukujiya, ukuhlanganiswa, ukunemba kwentambo kanye ne-flange, kanye nezimpawu zokulandelela.

Inqubo yokuhlola ingenziwa ngokulandelana okulandelayo: Ukuhlolwa kwezinto zokusetshenziswa → Ukuhlolwa kokucubungula → Ukuhlolwa kokusebenza komkhiqizo okuqediwe → Ukwamukelwa kokugcina. Isici ngasinye sichazwa kanye nezindlela nezindinganiso ezithile.

Inqubo Yokuhlola I-Butterfly Valve

1. Ukuhlolwa Kwezinto Ezingavuthiwe

1.1 Inhloso

Ukuqinisekisa ukuthi izinto zokusetshenziswa ezifana nomzimba we-valve, ipuleti le-valve, isiqu se-valve, kanye nendandatho yokuvala ziyahlangabezana nezidingo ezijwayelekile.

1.2 Izinto Zokuhlola:

-Ukuhlaziywa Kokwakheka Kwamakhemikhali: Usebenzisa i-spectrometer noma indlela yokuhlaziya amakhemikhali, qinisekisa isitifiketi sezinto ezibonakalayo ukuqinisekisa ukuhambisana nezindinganiso zezinto ze-ASTM/GB/EN.

-Ukuhlolwa Kokusebenza Kwemishini: Ukusampula kwenziwa ukuze kuhlolwe ukuthambekela, ukujiya, ukunwebeka, kanye nokuhlolwa komthelela.

-Ukuhlonza Izinto Nokulandelela: Iqoqo ngalinye lezinto zokusetshenziswa kumele lihlonzwe ngenombolo yesithando salo ukuqinisekisa ukulandeleka kwemvelaphi.

-Ukuhlolwa kwe-Metallographic (Ongakukhetha): Hlola ama-castings ukuze uthole amaphutha afana nokufakwa kwe-slag kanye ne-porosity.

2. Ukuhlolwa Kobukhulu

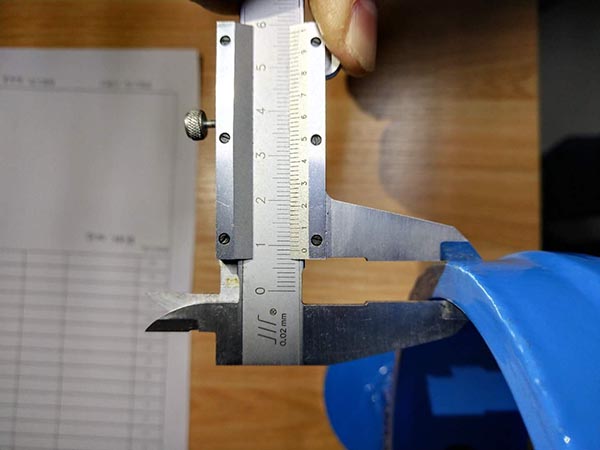

Amathuluzi: Ama-caliper e-Vernier, i-gauge yobubanzi bangaphakathi, i-depth gauge.

2.1 Inhloso

Ukuqinisekisa ukuthi ubukhulu bomkhiqizo buhambisana nemidwebo ejwayelekile ukuze kube lula ukufaka nokushintshana.

2.2 Izinto Zokuhlola

Ubude bomzimba wevalvu (ubukhulu bobuso nobuso)

Isikhala sembobo yokuxhumanisa i-Flange, ububanzi bembobo, incazelo yentambo

Ubukhulu bepuleti le-valve kanye nokususwa komphetho

Ukujula kwentambo nokubekezelelana kwayo

3. Ukuhlolwa Kwerabha Nesihlalo

Izinto Ezivamile: EPDM, NBR, VITON, PTFE.

3.1 Inhloso

Ukuqinisekisa ukumelana nengcindezi, ukumelana nokushisa, kanye nokumelana nokugqwala kwezinto zokuvala.

3.2 Izinto Zokuhlola

Ukuqinisekiswa Kwezinto Ezibalulekile

Hlola ukuthi ubuso bubushelelezi kangakanani, ukungabikho kwama-burrs, amabhamuza, kanye nokungcola.

Hlola ubukhulu obuyinhloko bendandatho yokuvala, njengobubanzi obuphakathi nendawo kanye nobubanzi obungaphakathi nobangaphandle.

Ubulukhuni berabha (isihloli sobulukhuni sase-Shore), isethi yokucindezela, amandla okudonsa, njll.

Ukuhlolwa kokumelana nokuguguleka

Ukulingana kwepuleti le-valve nobuqotho

4. Ukuhlolwa Kokumboza

4.1 Inhloso

Ukuqinisekisa ukuthi ukumelana nokugqwala, ukunamathela, kanye nobukhulu bengubo kuhambisana nezindinganiso.

4.2 Izinto Zokuhlola

Ukwelashwa kwangaphambilini (ukususwa kokugqwala) izinga ngaphambi kokufutha (Sa2.5 noma ngaphezulu, akukho silinganiso noma ukugqwala okubonakalayo)

Ubukhulu bokumboza ngemva kokufutha (kusetshenziswa igeyiji yobukhulu bokumboza)

Ukunamathela kokumboza (ukuhlolwa kokunqunywa okuphambene, isikhala esingu-1mm, indawo yokumboza ekhuhlayo ≤5% ngemva kokususwa kwetheyiphu)

Ukuhlolwa kokubukeka (ukugoba, imigodi, amabhamuza, ikhasi eliwolintshi, umehluko wombala)

Ukuhlolwa kokuqina kokumboza kanye nokumelana nokugqwala kosawoti

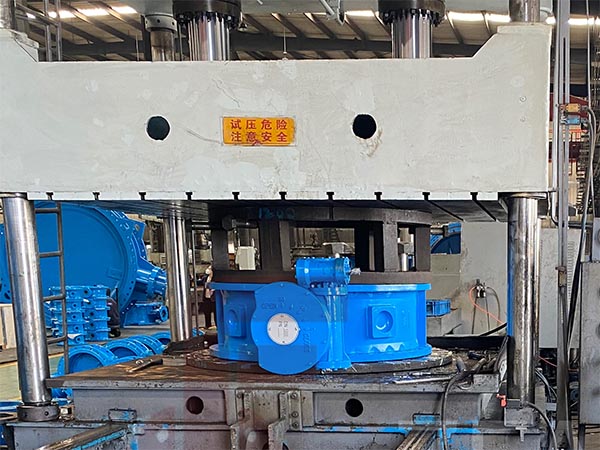

5. Ukuhlolwa Kokucindezela Nokuvuza

5.1 Inhloso

Ukuqinisekisa ukuthi i-valve ayivuzi ngaphansi kwengcindezi elinganisiwe.

5.2 Izindlela Zokwamukela

Umzimba wevalvu nazo zonke izingxenye ezithwala ingcindezi akumele zibe nomonakalo wesakhiwo, ukuguquka okungapheli, noma ukuvuza.

5.3 Izinto Zokuhlola

Ukuhlolwa Kwamandla Egobolondo: Ukuhlolwa kwe-hydrostatic ngengcindezi elinganisiwe izikhathi ezingu-1.5, isikhathi sokubamba ≥ imizuzu emi-2.

Ukuhlolwa Kokuvala: Ukuhlolwa kokuvala phambili nangemuva ngokucindezela okulinganiselwe izikhathi ezingu-1.1.

Ukuhlolwa Kokuqina Komoya: Thola ukuvuza okuncane usebenzisa umoya noma i-nitrogen ku-0.6 MPa.

Izinga Elijwayelekile Lokuvuza Okungazelelwe: Lihambisana nezimfuneko ze-API 598 / ISO 5208.

6. Ukuhlolwa kweTorque Yokusebenza

6.1 Inhloso

Ukuqinisekisa ukuthi i-torque yokuvula nokuvala iyahlangabezana yini nezindinganiso futhi ihambisana nezidingo zomklamo, ukuqinisekisa ukuthi iyunithi yokushayela iyahambisana.

Indlela Yokuhlola

Kukalwa kusetshenziswa ama-torque wrench kanye namamitha e-torque afana nama-actuator kagesi; qhathanisa i-torque yomklamo ne-torque elinganisiwe.

7. Ukuhlola Okubonakalayo Nokumaka

7.1 Inhloso

Ukuqinisekisa ikhwalithi yokubukeka kanye nemininingwane yokumaka.

7.2 Izinto Zokuhlola

Akukho mingxunya yensimbi, i-welding slag, amabala kawoyela, noma okunye ukungcola ngaphakathi.

Akukho mifantu, ama-burrs, noma ukugqwala. Ububushelelezi bendawo kanye nokuvumelana kombala. Ulwazi lwe-nameplate (imodeli, isilinganiso sokucindezela, izinto, umcibisholo wesiqondiso sokugeleza) lucacile, luphelele, futhi luphephile.

8. Ukuhlolwa Kokusebenza

8.1 Inhloso

Ukuqinisekisa ukuthembeka nokusebenza kahle kwevalvu.

8.2 Izinto Zokuhlola

Ukuguquguquka kokuvula nokuvala ipuleti le-valve

Ukunemba kokubekwa kwesikhundla se-valve

Ukulinganiswa kwe-coefficient yokumelana nokugeleza (inani le-Cv)

Ukuvumelana kwesiqondiso sokugeleza koketshezi

9. Ukuhlolwa Kokugcina kanye Nokuhlolwa Kwefektri

9.1 Inhloso

Ukunquma ngokuphelele ukuthi umkhiqizo uyafaneleka yini futhi ulungele ukuthunyelwa.

9.2 Kufaka phakathi

Ukubuyekezwa kwamarekhodi okuhlolwa

Ukunamathisela isitifiketi sokuhambisana namalebula okuhlola

Ukuthi iphakheji ivikela ngempumelelo yini ekulimaleni ngesikhathi sokuthuthwa, nokuthi ngabe kukhona yini izivalo ezivikelayo ebusweni be-flange kanye nemikhawulo enezintambo.

Isikhathi sokuthunyelwe: Okthoba-28-2025