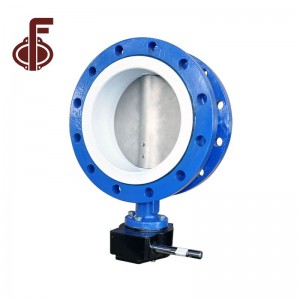

I-Lever CF8 Disc Soft Seat Wafer Butterfly Valve DN100 PN16

Imininingwane Yomkhiqizo

| Usayizi kanye nesilinganiso sokucindezela kanye nokujwayelekile | |

| Usayizi | I-DN40-DN1200 |

| Isilinganiso Sokucindezela | PN10, PN16, CL150, JIS 5K, JIS 10K |

| Ubuso Nobuso Izifo Ezithathelwana Ngocansi | I-API609, BS5155, DIN3202, ISO5752 |

| Uxhumano lwe-STD | I-PN6, PN10, PN16, PN25, 150LB, JIS5K, 10K, 16K, GOST33259 |

| I-Upper Flange STD | I-ISO 5211 |

| Izinto | |

| Umzimba | Insimbi Ebunjiwe (GG25), Insimbi Ebunjiwe (GGG40/50) |

| Idiski | I-DI+Ni, Insimbi Yekhabhoni (WCB A216), Insimbi Engagqwali (SS304/SS316/SS304L/SS316L), Insimbi Engagqwali Ephindwe Kabili (2507/1.4529), Ithusi, I-DI/WCB/SS embozwe nge-Epoxy Painting/Nylon/EPDM/NBR/PTFE/PFA |

| Isiqu/Umgodi | I-SS416, i-SS431, i-SS304, i-SS316, i-Duplex Stainless Steel, i-Monel |

| Isihlalo | I-NBR, i-EPDM/REPDM, i-PTFE/RPTFE, i-Viton, i-Neoprene, i-Hypalon, i-Silicon, i-PFA |

| Ukuthungwa kwezihlahla | I-PTFE, ithusi |

| Indandatho ye-O | I-NBR, i-EPDM, i-FKM |

| I-Actuator | I-Hand Lever, Ibhokisi Legiya, I-Electric Actuator, I-Pneumatic Actuator |

Ukuboniswa Komkhiqizo

Inzuzo Yomkhiqizo we-worm gear wafer bfv valve

1. Idiski yevalvu iqhutshwa yisibambo esijikelezayo esingu-90°, esivumelana nezinga le-interface le-ISO 5211.

2. Amapuleti e-valve ensimbi engagqwali afanelekela amapayipi aphatha imidiya ebolile ekudleni naseziphuzweni noma ekucutshungulweni kwamakhemikhali.

3. Indandatho yokuvala ehlanganisiwe ye-EPDM ifakwa emzimbeni wevalvu ukuze kufezwe ukuvuza okungekho phakathi kwediski yevalvu nomzimba wevalvu.

4. Ukuvuza okungaqondile kwe-Bidirectional zero, izinga lokushisa lingashintshashintsha kusuka ku--10°C kuya ku-+110°C.

5. Ifektri inesitifiketi sekhwalithi yesistimu ye-ISO 9001 futhi inenqubo ephelele yokukhiqiza ehlanganisa ukucutshungulwa kwe-CNC kanye nokutholwa kokuvuza.

6. Ukukhiqizwa kwangaphakathi kuqinisekisa amanani ancintisanayo, izikhathi zokulethwa ezilawulekayo, kanye nezinsizakalo zokwenza ngokwezifiso ze-OEM/ODM, okunikeza amakhasimende izixazululo eziphelele zamavalvu.

Imibuzo Evame Ukubuzwa ye-Two Shaft Wafer butterfly valve

U: Ingabe ungumFektri noma unguMhwebi?

A: Siyifektri enolwazi lokukhiqiza lweminyaka eyi-17, i-OEM yamakhasimende athile emhlabeni jikelele.

Q: Iyini isikhathi sakho senkonzo yangemva kokuthengisa?

A: Izinyanga ezingu-18 kuyo yonke imikhiqizo yethu.

U: Uyayamukela yini idizayini eyenziwe ngokwezifiso ngosayizi?

A: Yebo.

U: Ithini imigomo yakho yokukhokha?

A: T/T, L/C.

U: Iyiphi indlela yakho yokuhamba?

A: Ngolwandle, ngendiza ikakhulukazi, samukela nokulethwa okusheshayo.

Q. Iyini i-Worm Gear Operated CF8 Disc Double Stem Wafer Butterfly Valve?

I-CF8 disc esebenza ngegiya lezibungu ephindwe kabili i-wafer butterfly valve uhlobo lwe-valve yezimboni esetshenziselwa ukulawula ukugeleza koketshezi ngepayipi. Isebenza ngomshini wegiya lezibungu futhi ine-CF8 disc eneziqu ezimbili ukuze kube namandla nokuqina okwengeziwe.

Q. Yiziphi izinhlelo zokusebenza eziyinhloko zalolu hlobo lwe-butterfly valve?

Lolu hlobo lwe-butterfly valve luvame ukusetshenziswa ezimbonini ezahlukahlukene okuhlanganisa amakhemikhali, i-petrochemical, uwoyela negesi, amanzi namanzi angcolile, ukukhiqizwa kukagesi, kanye ne-HVAC. Lufanele ukusetshenziswa okujwayelekile kanye nezimboni.

U. Yiziphi izici ezibalulekile zevalvu ye-butterfly ye-CF8 disc eqhutshwa yi-worm gear?

Ezinye izici ezibalulekile zalolu hlobo lwe-butterfly valve zifaka phakathi ukwakheka kwe-wafer encane ukuze kube lula ukuyifaka, idiski ye-CF8 eqinile ukuze isebenze kahle, ukwakheka kwe-stem ephindwe kabili ukuze kube namandla engeziwe, kanye nendlela yokusebenza kwegiya lezibungu ukuze kusebenze kahle futhi kulawulwe.

Q. Yiziphi izinto ezisetshenziswa ekwakhiweni kwaleli valuvu leveva?

Izinto eziyinhloko ezisetshenziswa ekwakhiweni kwe-CF8 disc esebenza nge-worm stem double stem wafer butterfly valve zihlanganisa insimbi engagqwali yomzimba kanye ne-disc, kanye ne-carbon stem ye-stem kanye nezinye izingxenye zangaphakathi. Lezi zinto zikhethwa ngenxa yokuqina kwazo kanye nokumelana nokugqwala.

U. Yiziphi izinzuzo zokusebenzisa i-valve ye-butterfly ye-CF8 disc double stem wafer esebenza ngegiya lezibungu?

Ezinye zezinzuzo zokusebenzisa lolu hlobo lwe-butterfly valve zifaka phakathi ukwakheka kwalo okuncane nokulula, ukulula kokufakwa, ukulawula nokusebenza okunembile, ukuthembeka, kanye nokufaneleka kwezicelo eziningi zezimboni. Futhi kuyabiza futhi kudinga ukulungiswa okuncane.