Emkhakheni wokulawula uketshezi lwezimboni,izivalo uvemvaneidlala indima ebalulekile ekulawuleni, ekuqondiseni, nasekuhlukaniseni ukugeleza koketshezi, amagesi, nama-slurries kumapayipi. I-valve yovemvane ene-flanged iwuhlobo olulodwa lokuxhumana, olunama-flanges abalulekile kuzo zombili iziphetho zomzimba we-valve, okuvumela ukuxhumana okuvikelekile okuboshiwe kuma-flange amapayipi.

Indlela yokuzungezisa ikota ye-ai-valve ye-butterfly ene-flangediyayihlukanisa kumavalvu alayini afana nesango noma ama-globe valves, enikeza izinzuzo ngesivinini nokusebenza kahle kwesikhala.

Lesi sihloko sizocubungula imininingwane yama-valve ovemvane ane-flanged, ahlanganisa ukwakheka kwawo, izinhlobo, izinto zokwakha, izinhlelo zokusebenza, izinzuzo kanye nokubi, ukufakwa, ukugcinwa, ukuqhathanisa namanye ama-valve, kanye nezitayela zesikhathi esizayo.

1. Incazelo kanye Nomgomo Wokusebenza

I-valve yovemvane ene-flanged iyi-valve ejikelezayo engama-degree angu-90 ebonakala ngediski elawula ukugeleza koketshezi ngokuzungeza kwesiqu. Umzimba we-valve ufaka ama-flange kuzo zombili iziphetho ukuze kuxhunywe amabholithi aqondile epayipini. Ama-valve ovemvane be-Flange afaka ama-flange aphakanyisiwe noma ayisicaba anezimbobo ze-bolt, ahlinzeka ngoxhumano oluqinile futhi oluzinzile olufanele izicelo eziphansi, eziphakathi, nokucindezela okuphezulu, kanye namadayamitha amancane, aphakathi, namakhulu.

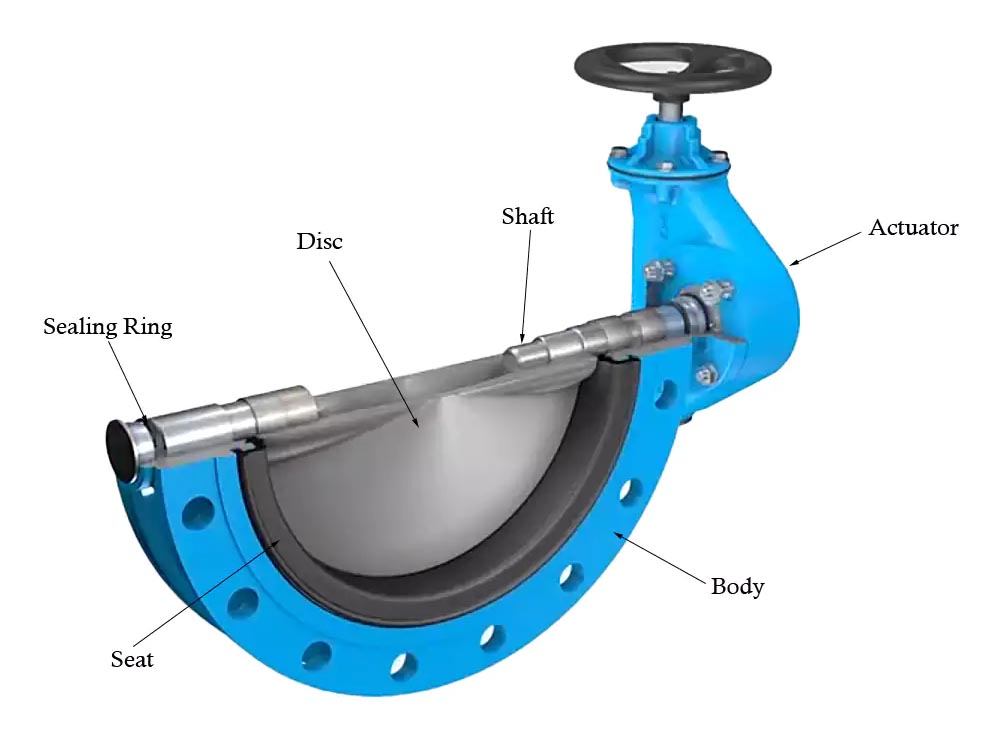

Isimiso sokusebenza silula futhi siyasebenza. I-valve iqukethe umzimba we-valve, i-valve disc, isiqu se-valve, isihlalo se-valve, kanye ne-actuator. Lapho isibambo noma igiya sisebenza, noma isiqu se-valve sizungeziswa yi-actuator ezenzakalelayo, i-disc ye-valve izungeza isuka endaweni ehambisana nendlela yokugeleza (evuleke ngokugcwele) iye endaweni e-perpendicular (ivalwe ngokugcwele). Endaweni evulekile, i-disc ye-valve ihambisana ne-axis yepayipi, ukunciphisa ukumelana nokugeleza nokulahlekelwa kwengcindezi. Uma ivaliwe, i-valve disc ivala ngokumelene nesihlalo ngaphakathi komzimba we-valve.

Lo mshini uvumela ukusebenza ngokushesha kwe-valve, ngokuvamile edinga kuphela ukuzungezisa okungama-degree angu-90, okuwenza asheshe kunama-valve ajike kaningi. Amavalvu ovemvane ane-flanged angakwazi ukuphatha ukugeleza kwe-bidirectional futhi ngokuvamile afakwe izihlalo eziqinile noma zensimbi ukuze kuqinisekiswe ukuvaleka okuqinile. Ukwakheka kwazo kuzenza zifaneleke ikakhulukazi kumasistimu adinga ukushintshwa njalo noma lapho isikhala silinganiselwe.

2. Izingxenye

Izingxenye eziyinhloko zihlanganisa:

- Umzimba weValve: Izindlu zangaphandle, ngokuvamile ukwakhiwa kwe-flange ephindwe kabili, inikeza ukuxhumana kwesakhiwo kanye nezindlu zezingxenye zangaphakathi. Insimbi ye-carbon isetshenziselwa ukusetshenziswa okuvamile, insimbi engagqwali yokumelana nokugqwala, ithusi le-nickel-aluminium isetshenziselwa izindawo zasolwandle, kanye nensimbi ye-alloy ezimweni ezimbi kakhulu.

- I-Valve Disc:I-elementi ejikelezayo, etholakala ngemiklamo eqondiwe noma eyisicaba, ilawula ukugeleza. I-disc ingaba phakathi noma i-offset ukuze kuthuthukiswe ukusebenza. Insimbi engagqwali, i-aluminiyamu yethusi, noma embozwe ngenayiloni ukuze kuthuthukiswe ukumelana nokugqokwa.

- Isiqu: I-shaft exhuma i-valve disc ku-actuator idlulisela amandla ajikelezayo. Insimbi engagqwali noma ama-alloys aphezulu amelana ne-torque.

Iziqu ze- through-shaft noma izingcezu ezimbili zivame ukusetshenziswa, zifakwe izimpawu zokuvimbela ukuvuza.

- Isihlalo: Indawo evalayo yenziwe ngempahla ye-elastomeric efana ne-EPDM noma i-PTFE. I-EPDM (-20°F kuya ku-250°F), BUNA-N (0°F kuya ku-200°F), Viton (-10°F kuya ku-400°F), noma i-PTFE (-100°F kuya ku-450°F) isetshenziselwa izigxivizo ezithambile; izinto zensimbi ezifana nensimbi engagqwali noma i-Inconel zisetshenziselwa izigxivizo eziqinile ezisezingeni eliphezulu.

- I-Actuator: Isebenza ngesandla (isibambo, igiya) noma inikwe amandla (i-pneumatic, kagesi).

- Ukupakisha kanye gaskets: Qinisekisa ukuthi ama-seal avuzayo aqinile phakathi kwezingxenye kanye noxhumo lwe-flange.

Lezi zingxenye zisebenza ndawonye ukuze zinikeze ukulawula okuthembekile.

3. Izinhlobo ze-Flanged Butterfly Valves

Ama-valve ovemvane ane-Flanged angahlukaniswa ngendlela elandelayo ngokusekelwe ekuqondaneni kwe-disc, indlela yokwenza i-actuation, kanye nohlobo lomzimba.

3.1 Ukuqondanisa

- I-Concentric (i-zero offset): Isiqu se-valve sidlulela phakathi nendawo yediski futhi sinesihlalo esiqinile. Le valve ilungele ukusetshenziswa kwengcindezi ephansi enamazinga okushisa afinyelela ku-250°F.

- I-Double Offset: Isiqu se-valve sisusiwe ngemuva kwediski futhi singekho phakathi nendawo, kunciphisa ukuguga kwezihlalo. Le valve ifanele ukusetshenziswa kokucindezela okuphakathi namazinga okushisa afinyelela ku-400°F.

- I-offset Kathathu: I-engeli ekhuphukile yokuhlala idala i-metal-to-metal seal. Le valve ifanele ingcindezi ephezulu (kufika ku-Class 600) kanye nezinga lokushisa eliphezulu (kufika ku-1200°F) izicelo futhi ihlangabezana nezidingo zokuvuza okuyiziro.

3.2 Indlela yokwenza

Izinhlobo ze-actuation zifaka i-manual, i-pneumatic, i-electric, ne-hydraulic ukuze kuhlangatshezwane nezidingo ezahlukene zokusebenza.

4. Izicelo Zemboni

Ama-valve ovemvane ane-Flanged asetshenziswa kabanzi emikhakheni elandelayo:

- Ukuhlanza Amanzi Namanzi Angcolile: Kusetshenziselwa ukulawula ukugeleza kwezitshalo zokwelashwa kanye nezinhlelo zokuphambukisa. - Ukucubungula Amakhemikhali: Ukuphatha ama-asidi, ama-alkali, nezincibilikisi kudinga izinto ezimelana nokubola.

- Uwoyela Negesi: Amapayipi kawoyela ongahluziwe, igesi yemvelo, nezinqubo zokucwenga.

- Amasistimu we-HVAC: Ilawula ukugeleza komoya namanzi kumanethiwekhi okushisa nawokupholisa.

- Ukukhiqiza Amandla: Ilawula isitimu, amanzi okupholisa, nophethiloli.

- Ukudla Nesiphuzo: Idizayini ehlanzekile yokuphatha uketshezi lwe-aseptic.

- Ezemithi: Ukulawula okunembayo ezindaweni eziyinyumba.

- I-Marine & Pulp & Paper: Isetshenziselwa amanzi olwandle, i-pulp, kanye nokucubungula kwamakhemikhali.

5. Izinzuzo kanye Nemibi ye-Flange Butterfly Valves

5.1 Izinzuzo:

- Ihlangene futhi ilula, inciphisa izindleko zokufakwa kanye nezidingo zesikhala.

- Ukusebenza okusheshayo kwekota kanye nokusabela okusheshayo.

- Izindleko eziphansi zamadayamitha amakhulu.

- Ukulahlekelwa kwengcindezi ephansi uma ivuliwe, iyonga amandla futhi isebenza kahle.

- Ilungele ukushintsha uketshezi ngokusebenza okuhle kakhulu kokuvala.

- Kulula ukuyigcina futhi iyahambisana nezinhlelo ezizenzakalelayo.

5.2 Okubi:

- I-valve disc ivimba indlela yokugeleza lapho ivuliwe, okuholela ekulahlekeni kwengcindezi ethile. - Umthamo wokudonsa olinganiselwe ezinhlelweni zokucindezela okuphezulu, okungase kubangele i-cavitation.

- Izihlalo zamavalvu athambile ziguga ngokushesha kakhulu kumidiya ehubhukayo.

- Ukuvala ngokushesha kungase kubangele isando samanzi.

- Eminye imiklamo idinga ama-torque okuqala aphezulu, adinga ama-actuator anamandla.

6. Indlela yokufaka iValve Butterfly

Ngesikhathi sokufakwa, qondanisa i-valve flange ne-flange yepayipi, uqinisekise ukuthi izimbobo zebholiti ziyahambelana.

Faka i-gasket ukuze uvalwe.

Vikela ngamabhawodi namantongomane, uqinise ngokulinganayo ukuvimbela ukuhlanekezela.

Ama-valve ane-flange kabili adinga ukuqondanisa kwezinhlangothi zombili ngesikhathi esisodwa; ama-valve ohlobo lwe-lug angafakwa ibhawudi ohlangothini olulodwa ngesikhathi.

Hlola inkululeko yokunyakaza yediski ngokugibela i-valve ngaphambi kokuyicindezela.

Uma ifakwe mpo, isiqu se-valve kufanele simiswe sivundlile ukuvimbela ukunqwabelana kwenhlabathi.

Hlala ulandela imihlahlandlela yomkhiqizi namazinga okuhlola afana ne-API 598.

7. Amazinga Nemithethonqubo

Ama-valve evemvane ane-Flangedkufanele ihambisane namazinga okuphepha nokusebenzisana:

- Idizayini: API 609, EN 593, ASME B16.34. - Ukuhlola: API 598, EN 12266-1, ISO 5208.

- Ama-Flanges: ASME B16.5, DIN, JIS.

- Izitifiketi: CE, SIL3, API 607.(ukuphepha komlilo).

8. Ukuqhathanisa Namanye Amavalvu

Uma kuqhathaniswa nama-valve esango, ama-valve ovemvane ane-flang asebenza ngokushesha futhi anikeza amandla okuntweza, kodwa amelana kancane nokugeleza.

Uma kuqhathaniswa nama-valve ebhola, ayonga kakhulu kumadiamitha amakhulu, kodwa ahlangabezana nokulahlekelwa kwengcindezi ephakeme ngesikhathi sokuvulwa.

Ama-valve eglobhu ahlinzeka ngokunemba okungcono, kodwa makhulu futhi abiza kakhulu.

Sekukonke, ama-valve ovemvane ahamba phambili ekusetshenzisweni komkhathi nokungabizi kakhulu.