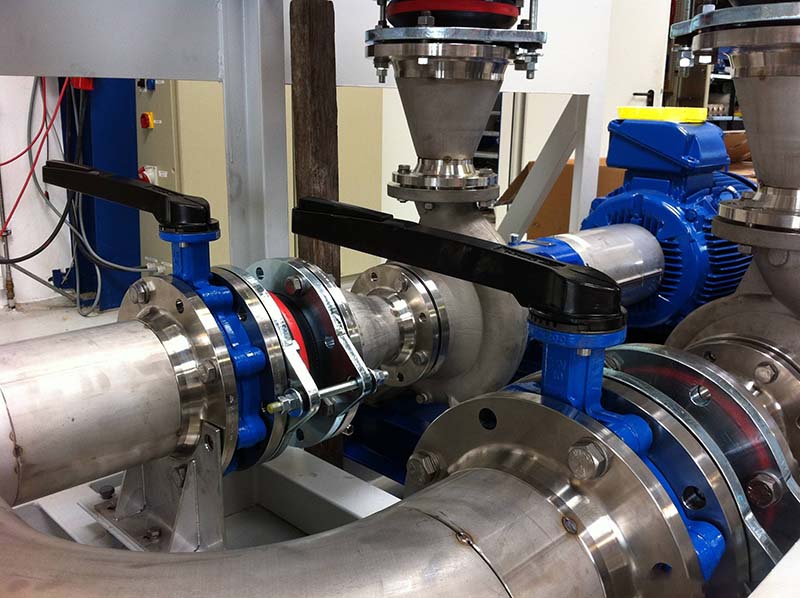

Ama-valve e-Butterfly asetshenziswa kabanzi ezimbonini ezifana nokwelashwa kwamanzi, uwoyela negesi, i-HVAC, kanye nokucubungula amakhemikhali ngenxa yokwakheka kwawo okufushane kanye nokugeleza okuphumelelayo kanye nokulawula okungabizi kakhulu.

Kodwa-ke, enye yezinkinga ezivame kakhulu ngeamavalvu ebhabhathaneukuvuza. Ukuvuza kungenzeka ngaphakathi (ngesihlalo sevalvu) noma ngaphandle (ezungeze isiqu sevalvu noma umzimba wevalvu). Ukuvuza kungaba kuncane noma kube kukhulu, okuholela ekunciphiseni ukusebenza kahle kohlelo, noma izingozi ezinkulu zokuphepha, izinkinga zemvelo, noma isikhathi sokungasebenzi esibizayo.

Ngakho-ke, ukuqonda izimbangela eziyinhloko zalokhu kuvuza nokusebenzisa izixazululo ezisebenzayo kubalulekile ukuqinisekisa ukusebenza kahle kwe-valve.

---

Izinhlobo Zokuvuza Kwevalvu Yebhabhathane

Ngaphambi kokubheka izimbangela nezixazululo, ake siqale sihlukanise ukuvuza okuvamile kuma-butterfly valve:

a. Ukuvuza Kwangaphakathi: Uketshezi ludlula ku-valve uma luvaliwe, okubonisa ukuthi isihlalo se-valve noma idiski ayikwazi ukwakha uphawu oluqinile.

b. Ukuvuza Kwangaphandle: Uketshezi luyaphuma emzimbeni wevalvu, ngokuvamile luzungeze isiqu sevalvu, ukupakisha, noma uxhumano lweflange, okonakalisa uphawu.

Zombili izinhlobo zokuvuza zingavela ekwakhiweni, ekufakweni, ekusebenzeni, noma ezicini ezihlobene nokugcinwa.

Ngezansi, sizohlola izimbangela eziyinhloko kanye nezixazululo ezihambisanayo zohlobo ngalunye lokuvuza.

---

1. Izisimbozo ezigugile noma ezonakele

Imbangela evamile yokuvuza kwangaphakathi ukuwohloka kwezingxenye zokuvala ama-valve (njengezingqimba ezinwebekayo noma izihlalo zensimbi).

1.1 Izimbangela

- Ukuwohloka kwezinto: Ukuchayeka isikhathi eside eziwuketshezi ezibolayo, amazinga okushisa aphezulu noma imisebe ye-ultraviolet kungabangela ukuthi izivalo ziqine, ziqhekeke noma zilahlekelwe ukunwebeka.

- Izinto ezilimazayo: Izinto eziqukethe isihlabathi, amatshe noma ezinye izinhlayiya zizodla izivalo ngokuhamba kwesikhathi.

- Ukuguga: Ngisho nangaphansi kwezimo ezingenzima kangako, izivalo zizowohloka ngokwemvelo ngokuhamba kwesikhathi, zinciphise ikhono lazo lokufaka idiski yevalvu. Lokhu ukuguga kwemvelo okungenakugwenywa.

- I-torque eyeqile: I-torque yama-actuator kagesi, omoya kanye nezinye izinto ezikhethiwe inkulu kakhulu, futhi idiski ye-valve ifaka ingcindezi enkulu esihlalweni se-valve lapho ivala, okwenza isihlalo se-valve siwohloke noma sidabuke. Ngisho noma sisetshenziswa ngesandla, ukusebenzisa i-torque eyeqile kuma-valve e-butterfly anobubanzi obukhulu kungabangela ukuguquka noma ukulimala kwesihlalo se-valve.

1.2 Izixazululo

- Ukukhetha izinto: Khetha izinto zokuvala ezihambisana noketshezi kanye nezimo zokusebenza. Isibonelo, sebenzisa i-PTFE yokumelana namakhemikhali, i-EPDM yokusetshenziswa kwamanzi, kanye ne-Viton yoketshezi olusekelwe kumafutha.

- Ukulungiswa okuvamile: Sebenzisa uhlelo lokulungisa oluvimbelayo ukuze uhlole futhi ufake ezinye izivalo ngaphambi kokuba zehluleke. Lokhu kubaluleke kakhulu ezindaweni ezinzima.

- Ukugqoka okuvikelayo: Ezisetshenzisweni ezirhabaxa, cabanga ngokusebenzisa amavalvu anezihlalo ezimboziwe noma eziqinile ukuze kwandiswe isikhathi sokuphila kwezivalo.

- Lungiselela i-actuator: Ngokwedatha ye-torque ye-butterfly valve enikezwe umenzi, khetha i-actuator ene-torque efanele, noma ukhethe i-actuator enesivikelo se-torque. Ngaphezu kwalokho, uma usebenza ngesandla, kufanele kugwenywe amandla amaningi. I-Zfa incoma ukuthi uma ungaqiniseki, ungasebenzisa i-actuator yesibambo noma yegiya lezibungu enomkhawulo we-torque.

---

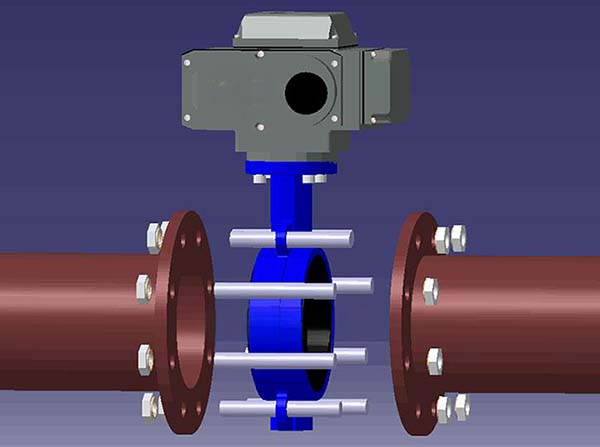

2. Ukufakwa okungafanele

Ukuvuza kuvame ukubangelwa amaphutha ngesikhathi sokufakwa kwama-valve, okuthinta izivalo zangaphakathi nezangaphandle.

2.1 Izimbangela

- Ukungalungi kahle: Uma ivalvu ingalungi kahle nepayipi, idiski ingase ingahlali kahle, okuholela ekuvuza kwangaphakathi.

- I-torque enganele: Ukuqina okunganele kwama-flange bolts kungabangela ukuvuza kwangaphandle endaweni yokuxhumana yepayipi le-valve.

- Ukuqinisa ngokweqile: I-torque eningi ingabangela ukuguguleka komzimba we-valve noma isihlalo, okungavimbela idiski ukuthi ivaleke ngokuphelele futhi kubangele ukuvuza kwangaphakathi.

2.2 Isixazululo

- Ukuhlola ukuhambisana: Ngesikhathi sokufakwa, sebenzisa ithuluzi lokuhambisana ukuqinisekisa ukuthi i-valve iphakathi nendawo epayipini. Kubalulekile futhi ukuqinisekisa ukuthi idiski ihamba ngokukhululeka ngaphandle kokuthinta udonga lwepayipi.

- Imininingwane ye-torque: Landela inani le-torque elinconywe ngumenzi lama-flange bolts bese usebenzisa i-torque wrench elinganisiwe ukuze ufinyelele ukucindezelwa okufanayo kwe-gasket.

- Ukukhetha i-Gasket: Sebenzisa ama-gasket asezingeni eliphezulu, ane-elastic ahambisana nezinto ze-valve kanye nepayipi. Qiniseka futhi ukuthi usayizi we-gasket uyafaneleka ukuze ugweme ukucindezelwa noma izikhala eziningi.

---

3. Ukuphazamiseka kwediski

Ukuvuza kwangaphakathi kungenzeka uma idiski ingakwazi ukuvala ngokuphelele ngenxa yokuphazamiseka ngokomzimba kwepayipi noma i-flange ezungezile.

3.1 Imbangela

- Ukungafani kobubanzi bepayipi: Uma i-ID yepayipi incane kakhulu, idiski ingashaya udonga lwepayipi lapho ivala.

- Umklamo we-Flange: Ama-flange anobuso obuphakanyisiwe noma izindawo zokuhlangana ezingalingani kahle zingavimba idiski ukuthi inganyakazi.

- Ukuqongelela udoti: Izinto eziqinile noma izikali eziqongelela ngaphakathi kwevalvu zingavimbela idiski ukuthi ihlale kahle.

3.2 Isixazululo

- Ukuqinisekiswa kokuhambisana: Ngaphambi kokufaka, qinisekisa ukuthi ububanzi bediski yevalvu buyahambisana ne-ID yepayipi.

- Ukulungiswa kwe-Flange: Landela izindinganiso ezifana ne-ANSI noma i-DIN ukuze usebenzise ama-flange ayisicaba noma ama-gasket ukuqinisekisa ukuthi i-disc ivulekile.

- Umsebenzi wokuhlanza: Hlanza uhlelo ngaphambi kokusebenza kwe-valve ukuze ususe udoti, bese ufaka izihlungi ezingenhla uma izimo zivuma ukuvimbela ukunqwabelana kwesikhathi esizayo.

4. Ukupakisha isiqu okuhlulekile

Ukuvuza kwangaphandle kuvame ukwenzeka eduze kwesiqu se-valve, okubangelwa izinkinga zokupakisha noma izivalo ezivimbela uketshezi ukuthi lungaphumi eceleni kwe-axis.

4.1 Imbangela

- Ukuguguleka: Ngokuhamba kwesikhathi, izinto zokupakisha ezifana ne-PTFE noma i-graphite zizoguguleka ngenxa yokunyakaza kwesiqu noma ingcindezi.

- Ukushintshashintsha kwezinga lokushisa: Ngokusekelwe esimisweni sokwanda nokuncipha kokushisa, ukushintshashintsha kwezinga lokushisa okuphindaphindiwe kungabangela ukuthi ukupakisha kunciphe, kukhululeke, futhi kuqhume ngisho.

- Ukulungiswa Okungafanele: Uma i-packing gland ikhululekile kakhulu, uketshezi lungavuza; uma luqinile kakhulu, lungalimaza isiqu se-valve noma luvimbele ukunyakaza.

4.2 Isixazululo

- Ukulungiswa kokupakisha: Hlola njalo futhi ushintshe izinto zokupakisha ezigugile.

- Izinto okufanele uzicabangele ngezinga lokushisa: Khetha izinto zokupakisha ezifanele izinga lokushisa lesistimu, njengezinto eziguquguqukayo ze-graphite zokusetshenziswa kokushisa okuphezulu.

- Ukulungiswa kwendlala: Qinisa indlala yokupakisha ku-torque echazwe umenzi, hlola ukuvuza ngemva kokulungiswa futhi ugweme ukucindezelwa ngokweqile.

---

5. Ukucindezela noma izinga lokushisa elidlulele

Uma izimo zokusebenza zidlula umkhawulo womklamo wevalvu, kungase kube nokuvuza, okuthinta izivalo zangaphakathi nezangaphandle.

5.1 Izimbangela

- Ukucindezela okweqile: Ukucindezela okweqile kwesilinganiso sevalvu kungalimaza isihlalo sevalvu noma idiski, okwenza kube nzima ukuvala.

- Ukwanda kokushisa: Amazinga okushisa aphezulu angabangela ukuthi izingxenye zande ngokungalingani, okubangela ukuguga kwesivalo, ukuthamba noma ngisho nokwakheka kwe-carbonization, okungathinta ukulingana kwendawo yokuvala, kukhulule isivalo noma kubangele ukuvuza kwangaphandle esibayeni.

- Ukuphuka okubandayo: Ngaphansi kwezimo ezingaphansi kwama-degrees angu-10, uphawu lungase luqhekeke futhi luqhekeke, okubangela ukuvuza.

5.2 Izixazululo

- Izilinganiso ezifanele zokucindezela kanye nokushisa: Khetha ama-valve anezilinganiso zokucindezela kanye nokushisa ezidlula izimo eziphezulu zesistimu bese ucabangela imingcele yokuphepha.

- Ukunciphisa ukucindezeleka: Faka ivalvu yokunciphisa ukucindezeleka noma isilawuli esingaphezulu ukuze uvimbele ukucindezeleka ngokweqile.

- Ukuvikela/ukushisa: Sebenzisa imikhono yokuvikela noma izinhlayiya zokushisa ezindaweni ezibandayo ukuze uvimbele ukubanda.

5.3 Ithebula lokuqhathanisa izinga lokushisa lezinto ezibonakalayo

Ngezansi kunezinhlobo zemidiya kanye namazinga okushisa ahambisana nezivalo zezinto ezahlukahlukene.

| IGAMA | IZICELO | ISILINGANISO SOKUSHISA |

|---|---|---|

| I-EPDM | Amanzi, amanzi aphuzwayo, amanzi olwandle, utshwala, usawoti wemvelo oncibilikisiwe, izixazululo ze-mineral acid, izisekelo zamaminerali ze-alkaline | -10℃ kuya ku-110℃ |

| I-NBR | Amafutha amaminerali kanye nemifino, igesi, ama-hydrocarbon angenaphunga, amafutha ezilwane, amafutha emifino, umoya | -10℃ kuya ku-80℃ |

| I-VITON | Ama-asidi, amafutha, ama-hydrocarbon, amafutha emifino namaminerali, amafutha | -15℃ kuya ku-180℃ |

| Irabha Yemvelo | Usawoti, i-hydrochloric acid, izixazululo zensimbi, i-chlorine emanzi. | -10℃ kuya ku-70℃ |

| Irabha yeSilicon | Ukumelana nokushisa okuphansi nokuphezulu, izinga lokudla Ama-hydrocarbon, ama-asidi, izisekelo, ama-ejenti omoya | -10℃ kuya ku-160℃ |

| PU | ukusetshenziswa kwamakhemikhali okungenalo ulaka njengamanzi, amanzi angcolile kanye namanzi olwandle | -29℃ kuya ku-80℃ |

| I-HNBR | Amanzi, Amanzi Aphuzwayo, Amanzi Angcolile. | -53℃ kuya ku-130℃ |

| I-Hypalon | Ukuncibilika kwe-asidi yamaminerali, ama-asidi e-organic kanye ne-inorganic, izinto ezi-oxidizing, | -10℃ kuya ku-80℃ |

| I-PTFE | amanzi, uwoyela, umusi, umoya, ama-slurry, kanye noketshezi oluqothulayo | -30℃ kuya ku-130℃ |

| I-SS+Graphite | Izindawo ezinokushisa okuphezulu kanye nomfutho ophezulu, njengezinhlelo zomusi, izimboni zamakhemikhali kanye nephethiloli. | -200°C kuya ku-550℃ |

| I-SS+Stelite | konke okuphakathi nendawo | -200°C kuya ku-600°C |

---

6. Ukususwa kwesikhumba kanye nokugqwala

6.1 Kuyini ukucasuka

Ukuqhekeka kwe-cavitation kubangelwa ukwehla okungazelelwe kwengcindezi ye-liquid medium kuya ekucindezelweni komphunga koketshezi engxenyeni egobhozayo ye-valve (njengaphakathi kwepuleti le-butterfly kanye nesihlalo se-valve), okuholela ekushintsheni kwegesi kwendawo koketshezi ukuze kwakheke amabhamuza. Lapho la mabhamuza ethuthela endaweni enomfutho ophezulu noketshezi, ayawa ngokushesha, akhiqize amagagasi okushaqeka kanye nama-microjet, okubangela ukuguguleka kanye nomonakalo ebusweni bokuvala i-valve, isihlalo se-valve kanye nomzimba we-valve.

Nakuba ukugqwala kanye nokubola kuyinkinga yokusebenza kahle, kungabangela ukuvuza ngokungaqondile ngokulimaza indawo yokuvala.

6.2 Kuyini ukugqwala?

Ukugqwala kubangelwa ukusabela kwamakhemikhali noma kwe-electrochemical ebusweni be-valve ye-butterfly ngenxa yokuxhumana isikhathi eside nemidiya egqwalisayo (njenge-asidi, i-alkali, isixazululo sikasawoti noma umusi oshisa kakhulu), okuholela ekulimaleni kwendawo yokuvala i-valve, isiqu se-valve, isihlalo se-valve noma umzimba we-valve.

6.3 Izimbangela

- Ukwehla komfutho ophezulu: Izinguquko ezisheshayo zomfutho zizokhiqiza amabhamuza aqhumayo, azokonakalisa idiski yevalvu noma isihlalo sevalvu.

- Ukugeleza kokugqwala: Le ndawo iqukethe ama-asidi, ama-alkali, usawoti, njll., asabela ngqo ebusweni bensimbi, okwenza ubuso bokuvala kanye nomzimba we-valve kuncibilike kancane kancane noma kugqwale futhi kunciphe.

- Imidiya evuthayo: Uketshezi olusheshayo oluqukethe izinhlayiya luzoguga unqenqema lokuvala ngokuhamba kwesikhathi.

6.4 Izixazululo

- Ukulawula ukugeleza: Nquma kahle usayizi wevalvu ukuze unciphise ukwehla kwengcindezi bese usebenzisa izibalo ze-flow coefficient (Cv) ukuze uhlangabezane nezidingo zesistimu.

- Ukuthuthukiswa kwezinto: Khetha izinto ezingagqwali njengensimbi engagqwali noma izembozo eziqinile zama-disc e-valve nezihlalo ze-valve.

- Umklamo wesistimu: Nciphisa izinga lokugeleza ngokwandisa ububanzi bepayipi noma ukwengeza idivayisi yokunciphisa ingcindezi phezulu.

Ithebula Lenani Le-CV Eliyi-6.5

| Inani le-Cv - Isilinganiso Sokugeleza Kwezinga DN50 kuya ku-DN1400 | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Usayizi(mm) | 10° | 20° | 30° | 40° | 50° | 60° | 70° | 80° | 90° |

| 50 | 0.1 | 5 | 12 | 24 | 45 | 64 | 90 | 125 | 135 |

| 65 | 0.2 | 8 | 20 | 37 | 65 | 98 | 144 | 204 | 220 |

| 80 | 0.3 | 12 | 22 | 39 | 70 | 116 | 183 | 275 | 302 |

| 100 | 0.5 | 17 | 36 | 78 | 139 | 230 | 364 | 546 | 600 |

| 125 | 0.8 | 29 | 61 | 133 | 237 | 392 | 620 | 930 | 1022 |

| 150 | 2 | 45 | 95 | 205 | 366 | 605 | 958 | 1437 | 1579 |

| 200 | 3 | 89 | 188 | 408 | 727 | 1202 | 1903 | 2854 | 3136 |

| 250 | 4 | 151 | 320 | 694 | 1237 | 2047 | 3240 | 4859 | 5340 |

| 300 | 5 | 234 | 495 | 1072 | 1911 | 3162 | 5005 | 7507 | 8250 |

| 350 | 6 | 338 | 715 | 1549 | 2761 | 4568 | 7230 | 10844 | 11917 |

| 400 | 8 | 464 | 983 | 2130 | 3797 | 6282 | 9942 | 14913 | 16388 |

| 450 | 11 | 615 | 1302 | 2822 | 5028 | 8320 | 13168 | 19752 | 21705 |

| 500 | 14 | 791 | 1674 | 3628 | 6465 | 10698 | 16931 | 25396 | 27908 |

| 600 | 22 | 1222 | 2587 | 5605 | 9989 | 16528 | 26157 | 39236 | 43116 |

| 700 | 36 | 1813 | 3639 | 6636 | 10000 | 14949 | 22769 | 34898 | 49500 |

| 800 | 45 | 2387 | 4791 | 8736 | 13788 | 20613 | 31395 | 48117 | 68250 |

| 900 | 60 | 3021 | 6063 | 11055 | 17449 | 26086 | 39731 | 60895 | 86375 |

| 1000 | 84 | 4183 | 8395 | 15307 | 24159 | 36166 | 55084 | 84425 | 119750 |

| 1200 | 106 | 5370 | 10741 | 19641 | 30690 | 46065 | 70587 | 107568 | 153450 |

| 1400 | 174 | 8585 | 17171 | 31398 | 49060 | 73590 | 112838 | 171710 | 245300 |

---

7. Amaphutha Okukhiqiza

Ngezinye izikhathi, ukuvuza kuvela ngenxa yeziphambeko ekwakhiweni kwamavalvu ezingatholakala ngesikhathi sokusetshenziswa kokuqala noma ukuhlolwa.

7.1 Izimbangela

- Amaphutha okuphonsa: Ukubhoboka noma ukuqhekeka emzimbeni wevalvu kungabangela ukuvuza kwangaphandle.

- Izinkinga zokuvala ubuso: Ukushintshwa kwediski noma isihlalo ngokungalingani kungavimbela ukuvalwa okufanele, okuholela ekuvuza kwangaphakathi.

- Amaphutha okuhlanganisa: Ukufakwa okungalungile kwezivalo noma ukungahleleki kahle kwezingxenye ngesikhathi sokukhiqiza kungabangela ukuvuza.

7.2 Izixazululo

- Ukuqinisekiswa kwekhwalithi: Thenga kubakhiqizi abadumile abanezitifiketi ezifana ne-ISO 9001, bese ucela umbiko wokuhlolwa kwengcindezi (isb., ngokusho kwe-API 598) ukuqinisekisa ukuthi akuvuzi.

- Ukuhlolwa kwangaphambi kokufakwa: Yenza ukuhlolwa kokuvuza kwe-hydrostatic noma kwe-pneumatic ngaphambi kokufakwa ukuze kutholakale amaphutha, bese ubuyisela amayunithi anephutha kumhlinzeki.

- Izimangalo zewaranti: Qiniseka ukuthi ivalvu iza newaranti emboza amaphutha okukhiqiza ukuze ikwazi ukushintshwa uma kutholakala ukuvuza kusenesikhathi.

---

8. Isiphetho

I-valve yebhabhathaneukuvuza, ukuxazulula lezi zinkinga kudinga inhlanganisela yokukhetha ivalvu efanele, ukufakwa ngokucophelela, ukulungiswa njalo, kanye nokwenza ngcono uhlelo. Ngokukhetha izinto ezifanele uhlelo lokusebenza, ukulandela imihlahlandlela yokufaka kanye nokuqapha izimo zokusebenza, abasebenzisi banganciphisa kakhulu ingozi yokuvuza.

Ukuvuza kwevalvu yebhabhathaneIzinkinga zingase zibangelwe yizici ezahlukahlukene, futhi kudingeka izixazululo ezahlukene zezinhlobo ezahlukene zokuvuza. Kungakhathaliseki ukuthi ukuvuza kwangaphakathi noma ukuvuza kwangaphandle, ngokuvamile kungabangelwa yizivalo ezigugile, amaphutha okufaka, ukuphazamiseka kwediski ye-valve, izinkinga zokupakisha isiqu se-valve, ukucindezela/ukushisa ngokweqile, amaphutha okukhiqiza noma ukugqwala. Ingozi yokuvuza kwama-valve e-butterfly ingancishiswa ngempumelelo ngokukhetha okunengqondo, ukufakwa okufanele, ukulungiswa njalo kanye nokusebenza okulungiselelwe. Ngezicelo ezibalulekile, ukubonisana nabakhiqizi bama-valve noma onjiniyela besistimu kungaqinisekisa ukusebenza okungenawo ukuvuza futhi kuthuthukise ukuphepha kohlelo kanye nokusebenza kahle.