Ngokusho kocwaningo nokuhlaziywa, ukugqwala kungenye yezinto ezibalulekile ezibangela umonakalo kuma-valve e-butterfly. Ngenxa yokuthi ingaphakathi lithintana ne-medium, liyagqwala kakhulu. Ngemva kokugqwala, ububanzi be-valve buba buncane futhi ukumelana nokugeleza kuyanda, okuthinta ukudluliselwa kwe-medium.ubuso bomzimba we-valveIfakwa kakhulu phansi noma ngaphansi komhlaba. Ubuso buthintana nomoya futhi umoya umanzi, ngakho-ke kulula ukugqwala. Isihlalo se-valve simbozwe ngokuphelele lapho ingaphakathi lithintana khona nendawo. Ngakho-ke, ukwelashwa kokugqoka ubuso bomzimba we-valve kanye nepuleti le-valve kuyindlela yokuvikela engabizi kakhulu ekugqwaleni endaweni yangaphandle.

1. Indima yokugqoka ubuso be-butterfly valve

01. Ukuhlonza izinto zomzimba we-valve

Umbala wengqimba engaphezulu usetshenziswa ezindaweni ezingakafakwanga umshini zomzimba wevalvu kanye nebhonethi. Ngale ndlela yokumaka umbala, singasheshe sithole izinto zomzimba wevalvu futhi siqonde kangcono izici zawo.

| Izinto Zomzimba Wevalvu | Umbala Wopende | Izinto Zomzimba Wevalvu | Umbala Wopende |

| Insimbi | Okumnyama | Insimbi Ehlanganisiwe | Okuluhlaza okwesibhakabhaka |

| Insimbi Ehlanganisiwe | Okumnyama | I-WCB | Okumpunga |

02. Umphumela wokuvikela

Ngemva kokuba ubuso bomzimba wevalvu bumbozwe ngopende, ubuso bomzimba wevalvu buhlukanisiwe nendawo ezungezile. Lo mphumela wokuvikela ungabizwa ngokuthi umphumela wokuvikela. Kodwa-ke, kumelwe kuphawulwe ukuthi ungqimba oluncane lopende alukwazi ukunikeza umphumela wokuvikela ophelele. Ngenxa yokuthi ama-polymer anezinga elithile lokuphefumula, lapho ungqimba luncane kakhulu, ama-pores esakhiwo avumela amanzi nama-molecule e-oxygen ukuthi adlule ngokukhululeka. Ama-valve okuvala okuthambile anezidingo eziqinile ekujikeni kongqimba lwe-epoxy resin ebusweni. Ukuze kuthuthukiswe ukungangeni kongqimba, ungqimba olulwa nokugqwala kufanele lusebenzise izinto ezakha ifilimu ezinomoya ophansi kanye nezigcwalisi eziqinile ezinezakhiwo zokuvikela eziphezulu. Ngesikhathi esifanayo, inani lezingqimba zokuvikela kufanele landiswe ukuze ungqimba lufinyelele ekujikeni okuthile futhi lube luqinile futhi lungabi nama-pore.

03. Ukuvimbela ukugqwala

Izingxenye zangaphakathi zopende zisabela nensimbi ukuze zidlulise ubuso bensimbi noma zikhiqize izinto ezivikelayo ukuze kuthuthukiswe umphumela wokuvikela wengubo. Kuma-valve anezidingo ezikhethekile, kufanele unake ukwakheka kopende ukuze ugweme imiphumela emibi kakhulu. Ngaphezu kwalokho, ama-valve ensimbi enziwe ngensimbi asetshenziswa emipayipini kawoyela angasebenza futhi njengezithibi zokugqwala kwemvelo ngenxa yemikhiqizo yokuwohloka ekhiqizwa ngaphansi kwesenzo samafutha athile kanye nesenzo sokomisa sensipho yensimbi.

04. Ukuvikelwa kwe-electrochemical

Lapho i-dielectric getting coating ihlangana nengaphezulu lensimbi, kuzokwakheka ukugqwala kwe-electrochemical ngaphansi kwefilimu. Izinsimbi ezinomsebenzi ophezulu kunensimbi zisetshenziswa njengezigcwalisi ezimbozweni, njenge-zinc. Izodlala indima yokuvikela njenge-anode yomhlatshelo, kanti imikhiqizo yokugqwala ye-zinc yi-zinc chloride kanye ne-zinc carbonate esekelwe kusawoti, ezogcwalisa izikhala efilimini futhi yenze ifilimu iqine, inciphise kakhulu ukugqwala futhi yandise impilo ye-valve.

2. Izimbozo ezivame ukusetshenziswa kuma-valve ensimbi

Izindlela zokwelapha ubuso bama-valve zifaka phakathi ukumbozwa ngopende, ukumbozwa nge-galvanizing kanye nokumbozwa nge-powder. Isikhathi sokuvikela sopende sifushane futhi asikwazi ukusetshenziswa ngaphansi kwezimo zokusebenza isikhathi eside. Inqubo yokumbozwa nge-galvanizing isetshenziswa kakhulu emapayipini. Kokubili ukumbozwa nge-hot-dip kanye nokumbozwa nge-electro-galvanizing kuyasetshenziswa. Le nqubo iyinkimbinkimbi. Ukwelashwa kwangaphambi kokwelashwa kusebenzisa izinqubo zokugaya kanye ne-phosphating. Kuzoba nezinsalela ze-acid kanye ne-alkali ebusweni bento yokusebenza, okushiya ukumbozwa Ingozi efihliwe yenza ungqimba lwe-galvaning lube lula ukuwa. Ukumelana nokumbozwa kwensimbi ye-galvanizing kuyiminyaka emi-3 kuya kwemi-5. Ukumbozwa nge-powder okusetshenziswa kuma-valve ethu e-Zhongfa kunezici zokumbozwa okujiyile, ukumelana nokumbozwa, ukumelana nokuguguleka, njll., okungahlangabezana nezidingo zama-valve ngaphansi kwezimo zokusetshenziswa kohlelo lwamanzi.

01. Ukugqoka umzimba we-valve epoxy resin

Inezici ezilandelayo:

·Ukumelana nokugqwala: Imigoqo yensimbi embozwe nge-epoxy resin inokumelana okuhle nokugqwala, futhi amandla okubopha ngekhonkrithi ancishiswa kakhulu. Ifanele izimo zezimboni ezindaweni ezinomswakama noma ezingcolisayo.

·Ukunamathelana okuqinile: Ukuba khona kwamaqembu e-polar hydroxyl kanye nezibopho ze-ether ezitholakala ku-epoxy resin molecular chain kwenza inamathele kakhulu ezintweni ezahlukahlukene. Ukuncishiswa kwe-epoxy resin uma iqiniswa kuphansi, ukucindezeleka kwangaphakathi okukhiqizwayo kuncane, futhi uqweqwe oluvikelayo akulula ukuwa futhi luhluleke.

·Izakhiwo zikagesi: Uhlelo lwe-epoxy resin olulungisiwe luyinto enhle kakhulu yokuvikela enezakhiwo eziphezulu ze-dielectric, ukumelana nokuvuza kwamanzi, kanye nokumelana ne-arc.

·Ayimelani Nokukhunta: Uhlelo lwe-epoxy resin olulungisiwe lumelana nezikhunta eziningi futhi lungasetshenziswa ezimweni ezishisayo ezinzima.

02. Izinto zepuleti le-valve nylon plate

Amashidi enayiloni amelana kakhulu nokugqwala futhi asetshenziswe ngempumelelo ezindleleni eziningi ezifana namanzi, udaka, ukudla kanye nokukhipha usawoti emanzini olwandle.

·Ukusebenza kwangaphandle: Isembozo sepuleti le-nylon singaphumelela ukuhlolwa kokufuthwa ngosawoti. Asikaze sihlubule ngemuva kokucwiliswa emanzini olwandle iminyaka engaphezu kwengu-25, ngakho-ke akukho ukugqwala ezingxenyeni zensimbi.

·Ukumelana nokuguguleka: Ukumelana nokuguguleka okuhle kakhulu.

·Ukumelana nomthelela: Azikho izimpawu zokuxebuka uma kushayisana ngamandla.

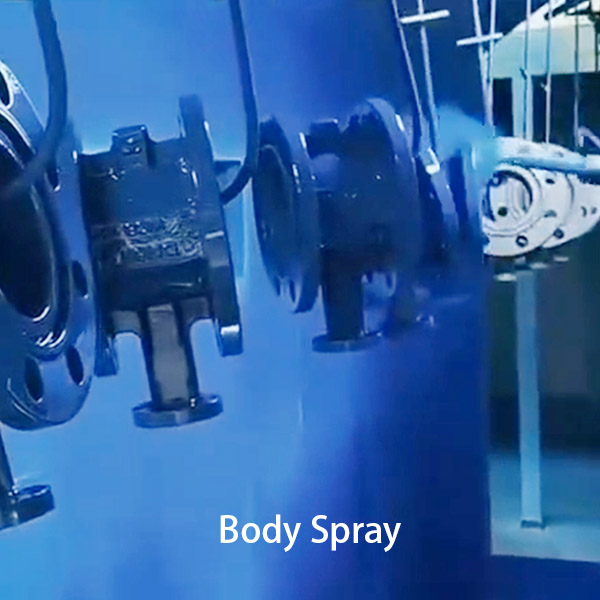

3. Inqubo yokufafaza

Inqubo yokufafaza iwukwelashwa kwangaphambi komsebenzi → ukususwa kothuli → ukufudumeza kusengaphambili → ukufutha (i-primer - ukusika - i-topcoat) → ukuqina → ukupholisa.

Ukufutha Ukufutha ikakhulukazi kusebenzisa ukufutha ngogesi. Ngokusho kosayizi wento yokusebenza, ukufutha ngogesi kungahlukaniswa kube umugqa wokukhiqiza wokufutha ngogesi kanye neyunithi yokufutha ngogesi. Lezi zinqubo ezimbili ziyafana, futhi umehluko omkhulu yindlela yokushintshana yento yokusebenza. Umugqa wokukhiqiza ngokufutha usebenzisa uchungechunge lokudlulisela ukuze kudluliselwe ngokuzenzakalelayo, kuyilapho iyunithi yokufutha iphakanyiswa ngesandla. Ubukhulu bengubo bulawulwa ku-250-300. Uma ubukhulu bungaphansi kuka-150 μm, ukusebenza kokuvikela kuzoncishiswa. Uma ubukhulu bungaphezu kuka-500 μm, ukunamathela kwengubo kuzoncipha, ukumelana nomthelela kuzoncipha, futhi ukusetshenziswa kwempuphu kuzokwanda.